After six installments of “Making Stuff,” we had a storage stuffed with machine instruments and the fundamental expertise to attract and construct nearly something we might ever need. And if something about machining, you’ve most likely been screaming at each web page: “WHAT ABOUT THE TOOLING!? TALK ABOUT THE TOOLING!”

Don’t fear, we heard you, however figured it made extra sense to introduce the machines first. Now that they’re all right here, it’s time to speak tooling.

What’s Tooling?

What precisely can we imply once we say “tooling?” It’s a broad time period in machining circles that principally means “all of the equipment you employ to make your components.”

Finish mills? Tooling. That vise? Tooling. Parallels? Collet blocks? Rotary desk? Tapping head? Proper angle attachment? Sure, sure and sure: That’s all thought of tooling, and we’ve solely scratched the floor with that checklist.

The frequent saying is, “You’ll spend way more on tooling than you’ll on any machine,” and in case you purchase new that’s completely appropriate. Finish mills can price a whole lot of {dollars} apiece, an honest vise is a virtually four-figure buy, and that’s earlier than you even get to the specialised stuff.

However in case you’re already engaged on vehicles, none of this can be too stunning. Certain, you are able to do fundamental upkeep with that $200 toolkit, however any lifelong mechanic may have a toolbox they’ve invested tens of 1000’s of {dollars} into over time.

Machine tooling works a lot the identical approach, with items being slowly purchased, repurposed or remodeled time as every venture requires it. This story will cowl our tooling journey over the primary yr or so, and at this level we’ve lastly stopped shopping for stuff each time we activate a machine. Name this the fundamentals for getting began.

Tooling Purchasing Fundamentals

So the place do you discover all this tooling? In case your uniform says “NASA” on it, then you definitely most likely purchase all of it new from trusted sources promoting high quality manufacturers. A bunch of business suppliers specialize on this kind of buyer, and McMaster-Carr is our favourite supply once we’re feeling bougie.

Take a couple of steps down from industrial suppliers and also you’ll discover a plethora of cheap imported tooling on websites like Amazon and eBay. Is it any good? Typically, no–the name-brand tooling is normally extra sturdy and extra correct–however we nonetheless have a good bit of stuff we purchased new from random imported manufacturers.

In lots of circumstances, “not as correct” received’t fly for fighter jets but is likely to be fantastic for components for previous vehicles, and generally we’re keen to sacrifice a couple of thousandths of precision for a whole lot of {dollars} in financial savings. Likewise, “not as sturdy” can imply that it’ll final only some years in our residence store as a substitute of a long time in a full-time enterprise.

Our favourite place to purchase tooling, although, is from different individuals who have already achieved the arduous work of accumulating it over a lifetime. Folks age, outlets shut, and time is a flat circle or no matter; which means used tooling is plentiful. As we had been tooling up, we purchased used gear from public sale web sites, in-person auctions, Craigslist and Fb.

This isn’t an exhaustive checklist of what you’ll must run a lathe and a mill in your store, however it’s a very good begin. That is the gear that obtained our residence store began, and the costs are roughly what we paid.

Measuring Instruments: $825

No, a tape measure isn’t correct sufficient to construct the components we needed to construct. We maintain including extra instruments to our measuring drawer, which has now expanded to a few full drawers of measuring instruments.

We’ve had points discovering dependable used measuring instruments, so as a substitute we purchase off-brand new gear with good opinions. We’re giving up some sturdiness, however accuracy appears to be proper on level.

At a minimal, you’ll want an honest dial caliper ($40) and a dial indicator ($40), however we extremely advocate a set of outdoor micrometers ($170) and a set of snap gauges ($25) to measure bores with extra accuracy.

We regularly use our dial check indicator ($45) and coaxial centering indicator ($110), as they’re nice methods to avoid wasting time. We’ve additionally splurged on some pre-made holders that we’ll name quality-of-life instruments: They only save a lot time versus establishing an indicator manually. These embody an indicator quill clamp for our Bridgeport ($50) and an Edge Expertise Professional Tram system ($100) that makes tramming our Bridgeport’s head easy.

We picked up a set of gigantic calipers ($100) to measure some Elva components we couldn’t precisely learn with our 6-inch set. Then there’s the used set of name-brand gauge blocks we purchased at an public sale ($60); they’ve proved invaluable for some measurements. We even have a machinist’s degree ($85) to make sure our lathe is chopping straight. Oh, and also you’ll want an edge finder for the mill; ours was kindly donated by 914Driver, a longtime member of GRM’s on-line neighborhood.

Angle Blocks and Parallels: $80

You’ll want these sooner moderately than later to precisely clamp stuff within the vise. An imported set of parallels ($40) units the peak of inventory, whereas an imported set of angle blocks ($40) allows you to exactly clamp them at an angle.

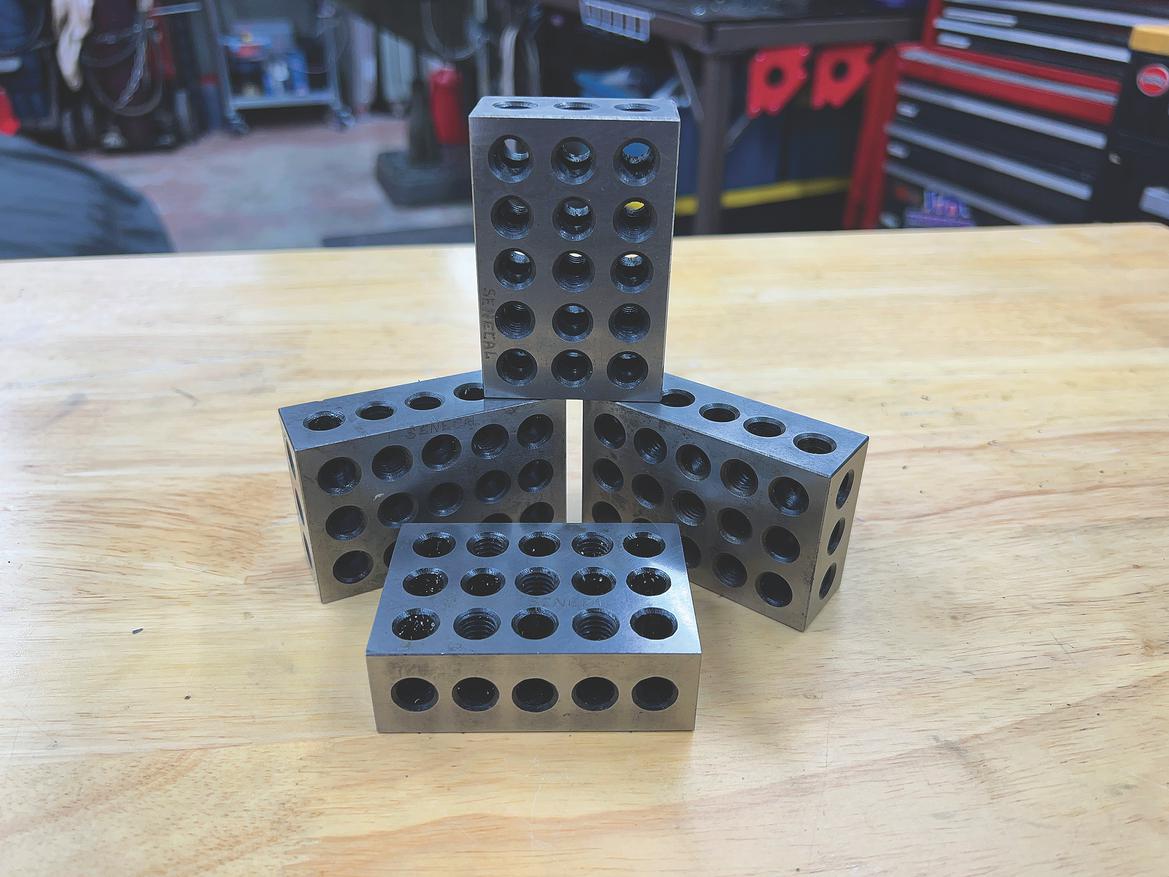

1-2-3 Blocks: $40

What are 1-2-3 blocks? They’re precisely what they appear like: blocks of metal which can be precisely 1x2x3 inches.

As a result of they’re floor sq. and flat, they’re extraordinarily helpful for clamping and measuring inventory on the mill. These had been one other beneficiant donation by 914Driver.

Used 6-inch Kurt Vise: $170

A vise is without doubt one of the instruments you’ll use most, and it’s additionally a serious contributor to accuracy when machining. In contrast to a bench vise that merely holds what you’re engaged on, a machinist’s vise is predicted to be completely straight and sq.–and to stay straight and sq. when clamping.

The recommendation we acquired was unambiguous: Purchase an actual Kurt vise or remorse each operation with an off model. Vises are measured by the width of the jaws, and 6 inches is ideal for a Bridgeport like ours. We scored a used Kurt with some drill marks for simply $170. New, a vise like that is an $800 buy.

Collet Blocks and Collets: $135

Collet blocks like this are nice for indexing spherical issues in a vise rapidly–whenever you’re chopping flats on a rod, for instance. We picked up a brand new set of imported collet blocks ($55) and paired them with a set of 5C collets ($80).

New Maintain-Down Set: $80

A lot of issues received’t slot in a vise, so that you’ll want hold-downs. We extremely advocate a fundamental set like this, which is bought underneath one million model names. Used hold-downs are an honest possibility in case you stumble throughout them for a steal, however they’re additionally most likely bent and broken. Use a brand new set like this as your baseline.

Software Holders and Collets: $150

All these finish mills and lathe instruments want a method to connect to the machine, and which means collets for the mill and AXA toolholders for the lathe. We once more selected new, imported tooling.

Small Drill Chucks: $70

We have now a field of used drill chucks mendacity round, however wished for smaller ones for day-to-day use on the mill and lathe. We solved the issue for $35 every on Amazon.

Rotary Desk: $440

How do you narrow any arc on a guide mill? You want a rotary desk, which lets you exactly rotate the desk with a little bit hand crank.

Typically, the larger, the higher, as an even bigger desk has extra steel so as to add rigidity and extra workspace on your fixtures. We needed no less than a 12-inch desk, however we actually needed a 15-inch desk.

Just like the vise, this can be a foundational software, so we needed an correct, sturdy, name-brand piece. After looking out regionally for greater than a yr with no luck, we discovered this used 15-inch Gorton for $300 on eBay and paid over $100 to ship it to our door.

Spin Indexer and Dividing Head: $380

We would have liked to chop a 36-spline axle on the mill, which means we would have liked a method to exactly index a component 10 levels at a time. A reasonable imported spin indexer ($80) makes use of the identical 5C collets as our collet blocks and may divide into any full-degree increments. That makes it an awesome price range various to an off-brand dividing head and chuck ($300), which might divide its rotation almost infinitely. One week after shopping for the spin indexer, we stumbled right into a venture that required the dividing head anyway, so now we personal each.

Boring Head: $110

That is one other software you’ll want early and infrequently when you’ve got a mill. Once more, we selected a brand new, imported mannequin from Amazon ($110). Boring heads maintain boring bars in a couple of positions and regulate in very fantastic increments, which means you possibly can create a exact gap of just about any dimension.

Finish Mills and Lathe Instruments: $350

Keep in mind once we stated you could possibly spend a whole lot on a single finish mill? Yeah, we obtained fortunate: A retired machinist posted his whole assortment–two full bins–of finish mills and high-speed metal lathe tooling on Fb Market for $25, and we had been the primary ones who confirmed up with money. A few of the instruments had been boring, some had been brand-new and most had been within the center, however they’ve been an awesome place to begin for our assortment.

Within the months since, we’ve made some new tooling with all that HSS, purchased a couple of finish mills for particular tasks ($100), and picked up a brand new set of imported carbide insert tooling for our lathe ($90). We additionally purchased a couple of imported boring bars ($80) for our Elva venture. Oh, and we would have liked a 2-inch face mill when constructing some Bugeye Sprite components, so we opted for an imported one from Amazon ($40).

4-Jaw lathe Chuck: $50

Our lathe didn’t include a four-jaw chuck, however we needed one to construct correct components. Fortuitously, we had one mendacity round from a earlier machine, however it wouldn’t thread onto our new lathe’s spindle. We saved a couple of steps and purchased a pre-threaded backing plate on Amazon ($50), then machined it into the lacking piece between our spindle and four-jaw chuck.

Large Angle Plate: $40

Some operations require the rotary desk to be mounted at a 90-degree angle, however not like most tables, ours didn’t have a second mounting face for vertical use. We purchased this 21-inch-tall metal angle plate at a neighborhood gear public sale.

Drawbar Wrench/Hammer Combo: $35

Certain, you should utilize a small hammer and a wrench, however this software saves time throughout each software change. We discovered it on Amazon.

Forklift: $450

You’re most likely questioning how a lot all this tooling weighs. The reply? Loads. Simply ask our poor UPS driver.

We discovered this small materials carry at a machine store liquidation public sale and took it residence for $450. It may well carry about 800 kilos, so it’s excellent for placing fixtures on and off the mill. After we’re not utilizing it, we retailer it underneath a bench, which means it successfully takes up solely a foot or so of house within the storage.

How A lot to Outfit a Residence Machine Store?

Hopefully you’re sitting down for this: Our tooling prices complete $3405, and that’s simply the key items we might keep in mind. If we went by the store with a fine-toothed calculator, we’re positive the full would high $4000.

What does this imply for our quest to construct a machine store at residence? Apparently it means we actually are dedicated, however no less than tooling up was a yearlong dying by a thousand cuts as a substitute of an enormous upfront fee.

Nearly each single software on this checklist was bought to sort out a job at hand, too, which means all of them characterize cash we didn’t spend at a neighborhood store. So possibly name every software the worth of training as effectively.

We’re sorry that there’s no nice takeaway from this installment aside from “Machine outlets are costly,” however hopefully this has supplied some readability into the final assertion that “Tooling is pricey.”

What’s subsequent for this collection? Now that the machine store is assembled, it’s time to get again to creating stuff. We’ll sort out our first sophisticated venture–one destined for the race monitor–within the subsequent installment.

Trending Merchandise