If it looks like this collection has been a bit unfocused, effectively, it has been. Whereas we’re fairly good at working a undertaking automotive collection, we’re whole amateurs at constructing a house machine store.

Now it’s time to leap the following hurdle holding us again: 3D scanning.

What 3D Scanning Can and Can’t Do

A couple of installments in the past, we wrote, “There’s no print button for a component you’ve drawn on the pc.”

After which we proved ourselves flawed by organising a 3D printer. However whereas there’s a straightforward path out of the pc, there’s no straightforward path into the pc.

Besides, that’s, for 3D scanning. The know-how works precisely the way it sounds: Level a magical system at your half, then watch it seem in a digital atmosphere. In idea, hours of laborious measuring and modeling could be utterly faraway from the workflow.

Why would you need this? As a result of only a few elements–particularly only a few elements in-built a house store–are designed within the laptop with the mandatory context round them.

Consider how aerospace engineers design an airplane half, maybe the touchdown gear. They don’t take a couple of tough measurements of the fuselage, draw a plain field within the laptop, then design a folding wheel mechanism that’s about the suitable dimension and slap it in there.

As an alternative, they’ve your entire airplane already modeled in software program from the beginning, which suggests the touchdown gear could be designed to suit completely, work together correctly with the present elements, be constructed with serviceability in thoughts and extra.

We all know, we all know: You’re not constructing a touchdown gear. However you’re most likely constructing alternator brackets, or turbo manifolds, or suspension elements, and even simply planning an engine swap.

And in contrast to these aerospace engineers, you possibly can’t precisely open up an in depth CAD mannequin of your automotive to see exactly how a lot room there’s below the hood or within the wheel effectively.

Except, that’s, you’ve got a 3D scanner. In idea, all you need to do is level it at your current elements, then abruptly you’ll have as a lot context as you’d like immediately seem within the laptop. Or, if you happen to’re simply copying current elements, a 3D scanner guarantees to be a real-life copier, unlocking a world of low-cost and simple alternative elements.

However the actuality isn’t fairly this easy. 3D scanners don’t truly mannequin actual elements within the laptop. As an alternative, they generate level clouds. And that’s a key limitation you’ll must learn about earlier than going any additional.

What’s the distinction? Nicely, let’s take that touchdown gear for instance. For those who have been going to attract it from scratch, you’d inform the pc, “It’s a cylinder the diameter and thickness of a wheel, with a rotating joint connecting it to a second cylinder the diameter and thickness of a touchdown gear assist.”

CAD individuals: We all know that’s an oversimplification. And airplane individuals: Do you actually assume we’d spend all our free time dragging residence outdated industrial gear if we truly knew something about planes? Simply bear with us for the remainder of this instance.

So let’s say you wished to take a 3D scan of that touchdown gear. You’d level your scanner on the half, then the pc would show: “It’s a cylinder the diameter and thickness of a wheel, with a rotating joint connecting it to a second cylinder the diameter and thickness of a touchdown gear assist.”

Proper? Unsuitable.

The pc would truly show a couple of thousand little dots, every at a selected coordinate in three dimensions. That is known as some extent cloud.

Zoom in, and it appears like any person spilled marbles everywhere in the flooring. However zoom out, and also you’ll notice this cloud is in the very same form as that touchdown gear. And after scaling it to match the actual world, the factors will nearly completely correspond to the actual world.

Decision, by the way in which, often refers back to the variety of factors and the space between them. Extra factors nearer collectively is greater decision. Fewer factors farther aside is decrease decision.

However sadly, some extent cloud isn’t almost as helpful as an actual parametric mannequin. Dimensions is usually a bit fuzzy, interfaces between elements could be robust to algorithmically decide, and errors and noise can happen. So whereas this 3D scan would offer you a very good thought of what that wheel appears like, it wouldn’t truly offer you an ideal wheel mannequin that you possibly can ship to the machine store. To get that, you’d most likely want to attract the wheel from scratch, utilizing the purpose cloud as a information to be sure to have been drawing it within the right location and on the proper dimension.

Look again to the 3D scan we did of our LS-swapped 350Z a couple of years in the past for a real-world instance. Although the scan got here out nice, it nonetheless required dozens of hours of modeling to show that knowledge right into a usable mannequin of our automotive.

So whereas 3D scans are nice for context, they’re not truly the silver bullet the uninitiated usually assume they’re. Nonetheless, although, they’re an immensely highly effective software. So right here’s learn how to do it in your house storage for just some bucks.

Kinds of 3D Scanners

We don’t have the house for an exhaustive breakdown of each kind of 3D scanner (see Wikipedia for that), however we’ll cowl the fundamentals.

The commonest kind of 3D scanner you’d discover in retailers isn’t what most individuals would even contemplate a scanner: Contact 3D scanners, like coordinate measuring machines, have been round for many years and file factors by touching them individually on the half.

A FaroArm is an instance, and so they’re nice for answering questions like, “The place are the bolt holes for my bumper mount situated?” However as a result of factors are collected separately, contact 3D scanners aren’t notably helpful for surfaces, particularly difficult ones. Chances are you’ll be affected person sufficient to scan your hood with a FaroArm, however it might most likely take you years to scan your entire engine bay.

Plus, there’s value: Funds many hundreds of {dollars} for a brand new FaroArm. For these with the means, although, it’s an business customary.

So let’s transfer on to the world of contactless 3D scanners, that are what most individuals image and work nice for surfaces. On the shopper stage, there are a pair methods to find out the form of an object with out touching it: energetic scanners and passive scanners. And we’ll return to oversimplifying to elucidate what these phrases imply.

Let’s take into consideration our touchdown gear once more, and this time we’re not fearful about scanning. We’re fearful about two animals: a bat and a human–or at the very least the way in which we perceive bats and people. We’re not zoologists or docs, however we did develop up watching Steve Irwin.

So let’s discuss how a bat sees that deployed touchdown gear. Mainly, it screams into the void, then makes use of its ears to pay attention for the sound of its cries bouncing off obstacles. This course of is known as echolocation, and also you perceive the fundamentals if you happen to’ve ever clapped your palms in an empty constructing and heard the echo.

The bat is figuring out the depth of its atmosphere by sending out indicators, then listening for the way lengthy it takes for them to bounce again–in the event that they bounce again in any respect. That’s the way it is aware of that there’s touchdown gear deployed from our airplane however clear air on both facet of it.

Substitute the bat with a laser or lightbulb, and the bat’s ears with a digital camera that may see the sunshine you’re emitting, and congratulations: You’ve constructed a digital bat. Transfer the laser or gentle round quick sufficient, and also you’ll have the ability to enhance the decision immensely, gathering increasingly more factors. Congratulations: You’ve constructed an energetic 3D scanner, and that is how lidar sensors and most industrial 3D scanning instruments work.

However human airline staff aren’t strolling round screaming on the touchdown gear. Or, if they’re, it’s solely as a result of Bob didn’t put air within the tires like he was speculated to. As an alternative, they use their eyes to find out what the touchdown gear appears like. And see we didn’t say “eye.” Certain, any person with an eye fixed patch will nonetheless see, however our depth notion comes from our pair of eyes spaced a couple of inches aside. They file the pure gentle bouncing off objects, then examine the 2 pictures so our brains can decide depth.

Substitute every eye with a digital camera, and your laptop can compute depth identical to your mind. Or you possibly can simply use one digital camera and transfer it round a bit of bit. You’ve constructed a digital eye with depth notion. However why cease at one eye? Computer systems are sensible, so why not use 1000 eyes without delay–or transfer your digital camera 1000 instances round a stationary object? Congratulations: You’ve constructed a passive 3D scanner. That is how a course of known as photogrammetry works.

Constructing a 3D Scanner at House

We’ve talked about why 3D scanning is helpful and about a couple of theoretical methods to perform it, and we will hear you screaming, “Simply inform me learn how to do it!” Nice, fantastic, right here’s the reply:

Spend $20,000 to $50,000 on a 3D scanner. See? It’s that straightforward.

We stored encountering value tags like that as we shopped the market of business scanners. Even the low finish of the market, with scanners aimed toward hobbyists like us, began slightly below $1000 and solely went up from there. At that value level, we simply didn’t see adequate functionality for the initiatives we wished to deal with.

Totally different 3D scanners for various duties. The FaroArm, widespread in motorsports and different industries, can very precisely measure numerous factors in house. However one isn’t in our price range. Pictures Credit score: Chris Tropea

Haven’t we scanned vehicles prior to now? Sure. Below the course of Morlind Engineering, we scanned our 350Z with photogrammetry. On our finish, that meant capturing 1000 images and importing them to a server. On Morlind’s facet, although, that required software program that was, once more, costlier than our automotive. One other useless finish.

Clearly, we’d want to determine our personal 3D-scanning resolution. So we raided our online game cupboard. Sure, critically: Microsoft bought an adjunct for years known as the Xbox Kinect, which might monitor the participant’s actions within the room. How? By continuously 3D scanning its atmosphere with a lidar sensor. Excellent.

What about constructing a low-buck 3D scanner? We tried that utilizing an Xbox Kinect hooked to a laptop computer. Pictures Credit score: Tom Suddard

We paired our second-generation Kinect with a USB adapter, an extension twine, a Home windows laptop computer in a backpack, and a few free software program from Microsoft, then walked across the storage and began scanning.

Assuming you have already got a Home windows laptop computer, you possibly can duplicate this setup for a couple of hundred {dollars}. However don’t, as a result of it simply didn’t work.

Over the course of some days, we tried scanning massive gadgets like vehicles and small gadgets like an influence steering pump, and we simply couldn’t constantly get usable information.

We encountered two points: On small gadgets, the Kinect’s decision simply isn’t that nice. Bear in mind, this system was designed to map rooms, the place a centimeter or two of error doesn’t matter. And on massive gadgets, the Kinect appeared to work fantastic, however our run-of-the-mill PC couldn’t actually sustain and we encountered frequent crashes and misplaced knowledge. We as an alternative added extra cables to attach the Kinect to a sooner desktop gaming PC, which helped, however the setup wasn’t actually transportable sufficient to make use of within the storage.

We finally acquired the Xbox Kinect to scan our Z, however solely a part of it earlier than crashing–and with out the excessive decision we hoped to get.

We’re fairly certain that with sufficient effort and time spent checking out bugs, the Kinect could possibly be a good 3D scanner for purposes the place accuracy isn’t that essential and also you don’t thoughts dragging an unwieldly {hardware} stack round. Nevertheless it turned increasingly more apparent that this wasn’t the right resolution we thought it might be.

Nonetheless pondering we wanted a handheld lidar scanner, we tried one other strategy: throwing cash on the downside. Our iPhone was due for an improve, anyway, so we drove to the Apple Retailer and gave them far an excessive amount of cash for the newest and biggest.

For a couple of generations now, Apple’s flagship smartphone has included a lidar sensor, and there are a couple of third-party apps that leverage its skills. We paired our $1200 telephone with a free app known as Polycam, then almost sprinted to the storage with pleasure. Lastly, we had an correct, inexpensive, easy-to-use 3D scanner. And we all know, we all know, it’s $1200, however odds are about 50/50 you’re studying this story whereas holding a contemporary iPhone anyway.

Don’t do that, both, as a result of it didn’t work. Just like the Kinect, the iPhone/Polycam lidar mixture simply wasn’t that correct. For large issues it labored effectively–we acquired adequate scans of a automotive or two–however zooming in on the small print, it was clear that the iPhone’s sensor was meant to scan rooms, not vehicles.

Hey, at the very least the brand new telephone’s digital camera was actually good. Which acquired us occupied with photogrammetry once more. Possibly, simply perhaps, we’d been barking up the flawed tree in our quest to seek out an accessible, energetic 3D scanner. Polycam has a toggle swap, and we swiped it from “Lidar” to “Photogrammetry” and began scanning.

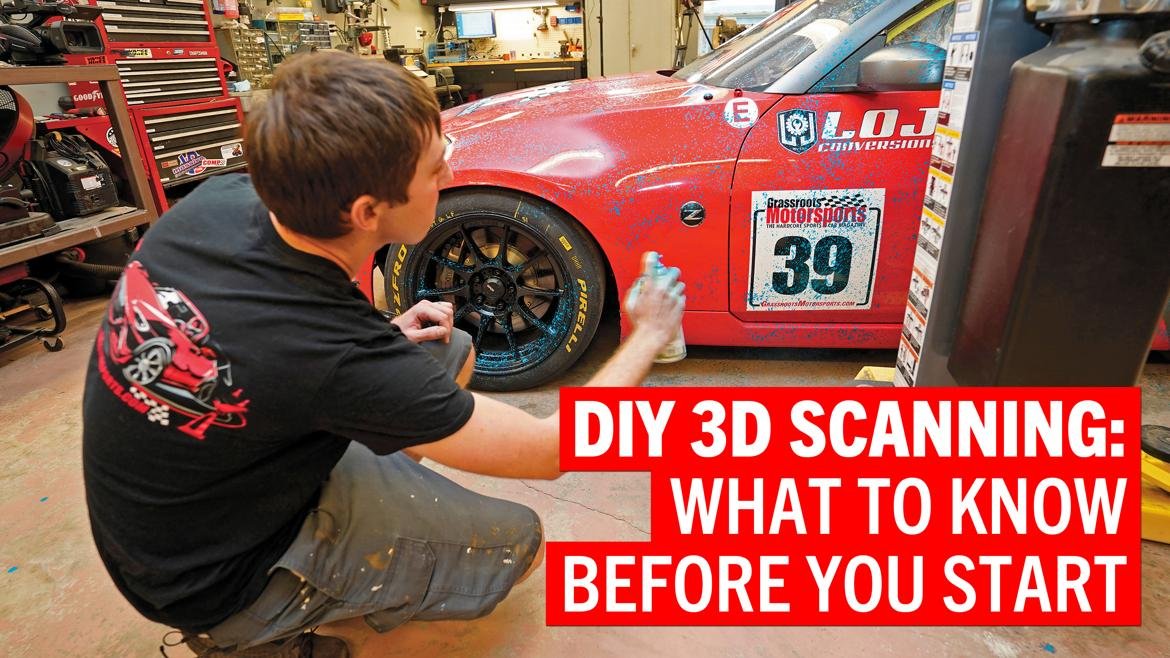

Yep, we’d lastly solved the puzzle. It took even lighting and a few sprayable chalk on reflective surfaces, however we have been quickly producing high-resolution, repeatable, usable 3D scans in our residence storage with nothing greater than an iPhone and a free app (although you’ll inevitably spend $17.99 per thirty days or $99.99 per yr for limitless captures when you burn by way of the free tier). We’re not sponsored by Polycam or something, so we’ll inform you that we solely subscribe each few months when we’ve some scanning to do.

A extra dependable resolution: our iPhone plus an app known as Polycam. Spray the automotive with detachable chalk paint, scan with the telephone, after which open correct 3D scans.

And even higher, you don’t want the newest and biggest iPhone to do that at residence. In truth, nearly any smartphone, or certainly any digital camera, will work. You’ll be able to add images at Polycam’s web site if you happen to don’t need to obtain the app.

Simply be sure to have even lighting (a couple of transportable worklights are loads) and order some washable sprayable sidewalk chalk by way of Amazon. Stick a bit of plastic or a drywall anchor on the tip of every spray can, and also you’ll have a dribbling, spitting coloured liquid that may create an ideal sample for scanning on something you’d like. And we haven’t discovered something it received’t wash off of but–apart from convertible tops.

Now that we’d lastly cracked 3D scanning, an entire new world of fabrication was unleashed. However that posed one other problem: We have been once more in a position to design extra difficult elements than we might manufacture. We’ll tackle that within the subsequent installment of this collection.

Trending Merchandise