[Editor’s Note: This article originally appeared in the May 2022 issue of Grassroots Motorsports. Some information and prices may have changed.]

Our collection on serving to each fabricator construct higher components began with the fundamentals: How to attract these components, design them with a pc, and instruct a sub-$200 3D printer to carry them to life from plastic. Now it’s time to begin reducing metallic.

The Residence Store Order of Operations

What ought to a annoyed CAD modeler purchase after they’re tired of the 3D printer? The reply is ideally “a machine store,” however keep in mind: We’re doing all this in a house storage on a traditional individual’s wage, which suggests $100,000 CNC mills are off the desk.

We purchased a Bridgeport knee mill and a fairly sized lathe, which we’ll cowl in future installments of this collection, as a result of we predict the most effective subsequent step is one other machine: the CNC router. For simply $200, this magical machine could make components to your race automobile out of actual supplies, like aluminum and carbon fiber.

What’s CNC?

Let’s begin with the primary a part of this new device’s identify: CNC. Most individuals consider CNC as a tool you should purchase, nevertheless it’s truly simply an adjective that may be put in entrance of any device.

That enormous milling machine you’re picturing? That’s a CNC mill. There are additionally CNC lathes, CNC plasma cutters, CNC sheet metallic brakes, CNC tubing benders and far, far more. If a device exits, odds are there’s a manufacturing unit someplace utilizing a CNC model of it.

CNC stands for pc numerical management, and it principally signifies that a pc–somewhat than a human–spins the knobs. The pc reads directions to understand how far to maneuver every axis and acts because the machine’s operator.

Why the clunky identify? Blame historical past. Earlier than CNC, there was NC. Numerical management meant machines learn directions from paper tape or related storage mediums. As soon as computer systems got here alongside, CNC turned the default expertise for many manufacturing machining work on the earth.

What’s the profit?

“I don’t care if I’ve to show the knobs manually,” you’re in all probability considering. “I simply need to construct one half for my race automobile. Who cares if it takes some further time?” We hear you, however not so quick. CNC machines aren’t simply considerably quicker than people, they’re able to superhuman feats, too: compound actions.

Consider a mill like your childhood Etch A Sketch, with one knob that controls the x-axis and one which controls the y-axis. Keep in mind making an attempt to attract angled traces? What a couple of circle? Suppose you could possibly draw a self-portrait?

Earlier than you head down the CNC rabbit gap, know two fundamentals: x-axis and y-axis. Keep in mind your Etch A Sketch? Identical idea however far more refined.

People simply can’t generate these advanced shapes in actual time, they usually actually can’t do it with the accuracy required for automobile components. Computer systems, although, don’t care. Inform them they will solely use an x and y knob to attract an ideal circle, they usually’ll knock it out of the park each time. That’s why CNC machines are extra than simply quicker variations of their human-operated counterparts.

Hey! Shut that grievance e mail! We all know that advanced shapes are doable from human fingers, too. We’re very pleased you’ve mastered your rotary desk and your 27-gear linkage tying your energy feed to your second axis. For the common dwelling builder, although, these methods are successfully inconceivable when making quite a lot of totally different components.

What’s a Router?

We’ve lined CNC, so let’s deal with the second a part of this new device’s identify: router. This one might be extra acquainted, and it’s lifeless easy: an electrical motor with a reducing bit on the top that removes materials. The motor, bit and materials can fluctuate broadly, however you get the fundamentals.

Put these phrases collectively, and the essential construction of a CNC router is smart. It’s a router with a bit that’s mechanically moved round a desk by some type of CNC-driven assist construction. And in case you’re considering this feels like a CNC mill, you’re proper.

We couldn’t discover a clear algorithm that categorizes machines as one or the opposite. Usually, although, routers have much less accuracy, much less rigidity and a a lot bigger work envelope. Mills can take heavier cuts on harder supplies with extra accuracy, however they sacrifice work envelope.

Right here’s a easy option to inform them aside: If it appears prefer it’s made to chop issues out of flat sheets, it’s in all probability a router. If it appears prefer it’s made to chop blocks of metallic, it’s in all probability a mill. Routers could be correct to about five-thousandths of an inch, whereas mills could be correct to inside just a few tenths of a thousandth of an inch.

The commonest dimension of CNC router appears to be a roughly 4×8-foot work envelope, as a result of most uncooked supplies are available in sheets that dimension. We’ll be speaking about one thing barely totally different for our personal store, the desktop CNC router, which is essentially the most accessible CNC machine on the planet. The commonest work envelope is concerning the dimension of a typical pocket book.

Meet the Mercury Capri of Routers

After we bought our Creality 3D printer, we known as it “the Miata of 3D printers” because of its first rate efficiency out of the field and a powerful aftermarket. Within the context of reducing aluminum, what we’re about to speak about is not a Miata. In actual fact, it’s nearer to a lesser copy that may barely, perhaps, type of do the job in query if handled gently.

So we’ll introduce our new device this fashion: Meet the Mercury Capri of routers. No, not the cool first-generation Capri. Not even the groovy second era. We’re speaking concerning the anemic, awkward-looking, front-wheel-drive third era that was mercifully killed after simply 4 mannequin years. That is the generic, imported 3018 CNC router, the underpowered hub of our components manufacturing unit.

Bought beneath varied model names and with varied equipment and enhancements, this router is named a 3018 because of its work envelope, 300x180mm (about an 11×7-inch rectangle).

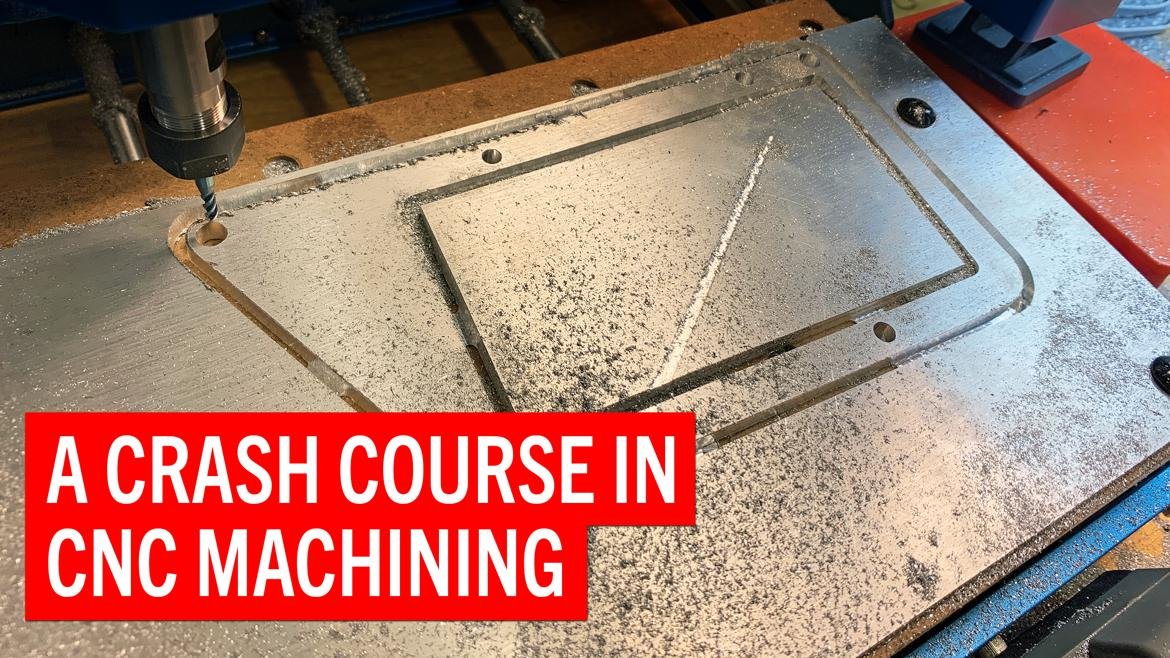

Our dwelling CNC journey began with a 3018-PROVer. After assembling it, we may assault a easy challenge: engraving keychain fobs utilizing our {custom} holder.

It prices as little as $200, and also you’ll discover scores of them on Amazon and eBay. It has about the identical energy as a Dremel, key components are manufactured from injection-molded plastic, and it’s not even technically a router. Most sellers name it an “engraver” since you’d must be insane to attempt taking deep cuts with it. However right here’s how we did it anyway.

For the princely sum of $314, we ordered the top-of-the-line 3018, a 3018-PROVer. That further $100 or so acquired us an offline controller, restrict switches, an emergency cease and a device contact probe. These are extraordinarily useful to your first machine, so we advocate splurging on related upgrades. It’s price noting that none of those make the machine extra highly effective, although, and you will get these similar outcomes with the most cost effective model.

After a night of tinkering, we’d assembled the 3018 and put in the equipped software program on an outdated laptop computer. It was time to begin constructing.

Fireplace Up the CAMputer

However having a machine doesn’t make you a machinist, and we had loads to be taught. Earlier than we may minimize something on our new CNC router, we wanted a program to load into it.

Similar to our 3D printer, our new CNC router runs on G-code, which is a set of directions that tells the machine the place to maneuver and how briskly to maneuver there. G-code’s format permits for personalization, too, and ours would inform the 3018 how briskly to spin its spindle as effectively.

Mainly, we don’t inform our machine, “We want a 350Z door deal with bracket.” As a substitute, we inform it, “Transfer in these instructions at this velocity.” That program, if written accurately, will end in a 350Z door deal with bracket.

[Project Car: LS-Swapped Nissan 350Z]

The 3018 can’t even learn G-code instantly. As a substitute, that outdated laptop computer we linked reads the code and requests the proper actions. Or, since we’ve got the flamboyant 3018, an included dongle can run G-code off an SD card and not using a laptop computer current.

So the place does G-code come from? Welcome to the following three-letter acronym: CAM, which stands for computer-aided manufacturing. CAM software program helps you flip your CAD mannequin into manufacturing directions, and Fusion 360, our most well-liked CAD bundle, features a CAM module free of charge.

We received’t get into the trivialities of CAM, as every software program bundle treats it otherwise, however right here’s the essential workflow: First, design the half. Then, fireplace up your CAM software program and inform it the fundamentals–your machine’s capabilities, what device(s) you’ll be utilizing, and what dimension and materials of inventory you’ll be making your half with.

When you’ve arrange the fundamentals, you’ll be able to construct particular person device paths to progressively chip away at inventory till solely your half is left. Two key components of this course of are feeds and speeds, that means how deep of a minimize the machine takes with every move and the way rapidly it strikes. Our 3018 is likely one of the least highly effective, least inflexible CNC machines in the marketplace, so we wanted to make use of extraordinarily mild feeds and very sluggish speeds.

When you’re glad, export your program to G-code, load it into the machine, and watch your half come to life.

Let’s Make a Half

For our first take a look at, we ordered a bunch of low-cost aluminum keychains and designed just a few easy take a look at packages. Our aim? See if our 3018 labored, damaging 50-cent inventory as an alternative of $50 inventory within the course of.

After some trial and error–and multiple damaged engraving bit–we have been in a position to make our personal {custom} aluminum keychains. Success!

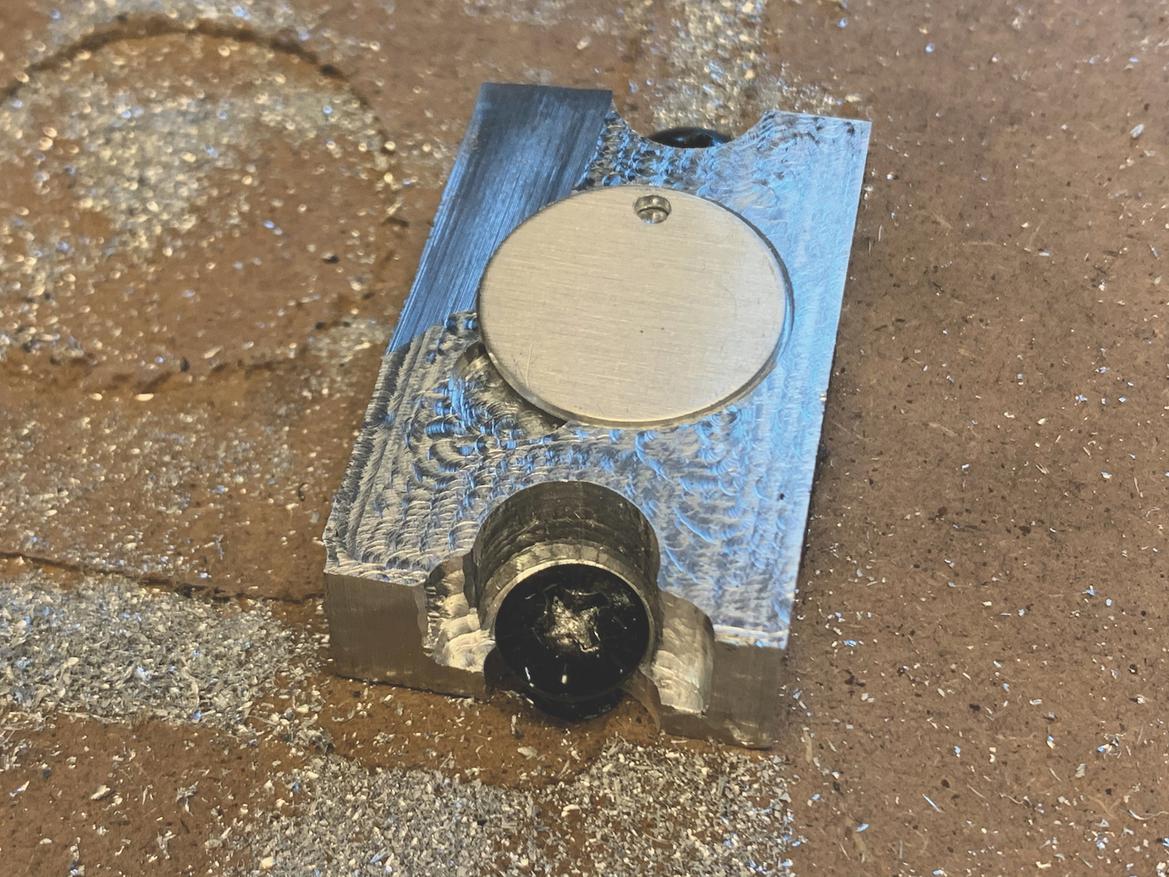

Emboldened, we determined to get fancy. Might the 3018 create advanced three-dimensional components out of aluminum? We fitted a 4mm router bit, clamped down a tiny block of 6061 aluminum, and had our reply just a few hours later. The 3018 carved a custom-made keychain fixture, our overengineered resolution to holding down every keychain for engraving. We have been formally CNC machining aluminum components.

After just a few extra assessments and a $20 upgraded spindle, we stepped as much as the large leagues and efficiently made a door deal with bracket for our 350Z on our little 3018 CNC. That settled it: It was doable to make aluminum components on this machine. It was on the far higher restrict of a 3018’s functionality, nevertheless it was doable.

Extra Commoditized Equipment: the 6040 CNC

But when we needed to chop aluminum effectively, we’d must stiffen the 3018, beef up the stepper motors, and add extra energy to the spindle. Oh, and we may actually, actually use a bigger work space, too.

This was far an excessive amount of work to waste on that little machine–akin to making an attempt to make a Mercury Capri out-handle a Miata. So we minimize bait. In any case, we’d purchased a generic piece of imported equipment as soon as and gotten away with it. Why not repeat that feat?

The 3018’s greater sibling is often known as a 6040, and it appeared to supply every part we needed. It was a a lot stiffer machine with a way more highly effective spindle and a a lot bigger work space.

We then graduated to a 6040 machine: extra energy plus the power to deal with greater CNC initiatives.

We acquired one on eBay for simply over $1000, then spent weeks making an attempt to get it to work. We do now have a working 6040 that cuts aluminum like a champ, nevertheless it was removed from plug and play. Try our 6040 CNC discussion board matter at grassrootsmotorsports.com/6040 for the blow by blow.

We’d discovered find out how to use CAD software program, printed components from plastic with a 3D printer, and now made them from aluminum with a CNC router. However let’s say you need to reinforce components–perhaps constructed from supplies like metal or stainless-steel. Or maybe you’re on the lookout for tolerances tighter than five-thousandths of an inch. We’ll make that leap within the subsequent installment, after we purchase our first “actual” piece of equipment.

Trending Merchandise