Anybody who’s ever had a monitor automobile has in all probability performed some aluminum fabrication. Whether or not that was a easy hand-formed bracket or a extra advanced construction, aluminum’s low price, ease of availability in big-box shops, excessive strength-to-weight ratio and principally benign nature make it the proper materials for even the novice fabricator.

However in the case of becoming a member of two items of aluminum, what’s the most effective technique? The reply is that there in all probability isn’t a single reply, however a variety of choices that adjust based mostly on the fabric, accessible time and talent of the fabricator. So the next–whereas not a whole checklist–will run by way of among the extra widespread choices you’ll probably have entry to in your house store, and the professionals and cons of every.

Self-Tapping Screws

Let’s face it, if it weren’t for self-tapping screws, there’d in all probability be no newbie motorsports passion. Self-tappers are the zip ties and duct tape of the {hardware} world, and their low-tech effectiveness has gotten us out of many a jam.

However their simplicity can be their weak spot. The threads of self-tapping screws leverage themselves towards the work materials with a reasonably coarse pitch, so in thinner supplies every thread doesn’t get a lot buy. For attaching skinny supplies to thicker supplies, they work higher.

We’ll additionally put common sheet-metal screws with a individually drilled pilot gap below this heading, however actually, who has time to seize two totally different drills when your screw can simply make a gap all by itself?

Professionals: Easy, one-operation fastener. Low cost and plentiful. Sturdy shear resistance. Can be utilized to connect disparate supplies. Can be utilized as a “blind” fastener (the place you haven’t any entry to the again of the fastener). Simply detachable.

Cons: Energy is extremely depending on materials thickness, and it’s not enormous in the most effective of circumstances. For optimum joint power, thickest materials have to be away from screw head. Not rotation resistant, and rotation could cause loosening. Creates sharp, pokey factor on reverse facet of joint. Removing is feasible, however every utility weakens the opening a bit. Gap must be the precise measurement.

Finest for: Emergency repairs, non-mission-critical or low-strength-requirement fabrications, short-term fastening throughout meeting, whenever you’ve simply given up.

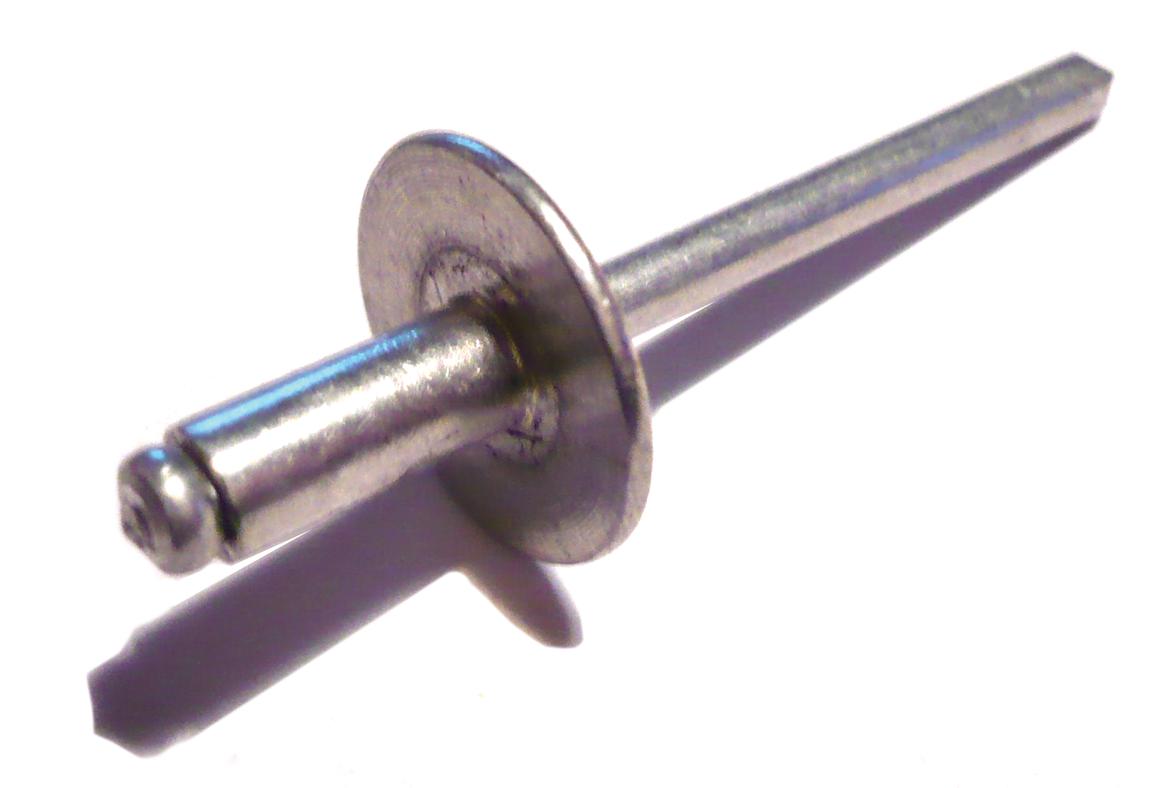

Aluminum Rivets

Rivets are the stylish individual’s self-tapper, and much more applicable–and better-looking–for everlasting constructions. When used with a backing washer, the rivet locations the load of the joint on the face of the fabric, moderately than counting on the bending pressure of the fabric to carry the threads as with a sheet-metal screw.

And people backing washers are fairly necessary. Rivets can be utilized as “blind” fasteners for attaching workpieces that may solely be accessed on one facet, however their very nature as ductile, deformable objects makes them inherently vulnerable to eventual loosening below load.

And whereas rivets are usually quick and simple to make use of, using finest practices is particularly necessary to get the strongest joint potential. Selecting the right rivet size for the connection is important. Rule of thumb: Rivet size needs to be equal to the overall gap depth (together with backup washer if employed), plus 1.5 instances the rivet diameter. Not that we’d ever suggest utilizing the flawed {hardware} for a mission, however should you’re ever in a jam, barely too lengthy is healthier than barely too brief.

Additionally, when fastening supplies of differing hardness, the strongest joint shall be achieved when the top (instrument finish) of the rivet is positioned on the softer of the 2 supplies.

Professionals: Glorious power, completed look, will be put in blind, available. Expands to suit the opening.

Cons: Requires a number of operations (drill, align, rivet). Extremely variable joint power relying on utility (materials thickness, washer use, and so forth.). Permits rotation. Can compress and deform gentle supplies. Extra advanced removing, however removing usually doesn’t have an effect on the workpiece.

Finest for: Light-weight fabrications that don’t should be disassembled to be serviced. Joints that may expertise lot of vibration. (Threaded fasteners are likely to loosen below vibrational stresses; rivets are extra vibration resistant however don’t cope with shock hundreds in addition to threaded fasteners.)

Bolted Connections

A bolted joint with a threaded fastener and a nut is the final word non-welded connection for aluminum–or another machinable materials. Usually, a correctly utilized bolted connection is as sturdy or stronger than the fabric round it when utilized in sheet or skinny plate functions. Correctly sized and constructed bolts have wonderful rigidity and shear resistance and are simply detachable with out lasting impact to the workpiece.

However bolted joints have their downsides. First, the joint have to be bodily configured so a bolted joint is feasible. Usually, this implies two flat, parallel surfaces on both facet of the joint with good contact between them. For butt joints or something missing flat mating surfaces, bolts normally aren’t the reply.

Plus, all threaded fasteners are vulnerable to vibrational loosening. This may be combatted with chemical-thread lockers and vibration-resistant washers like Nord-Locks, however it’s nonetheless a consideration in high-vibration environments.

Professionals: Sturdy, easy, available {hardware}. Extremely calculable power. Detachable. Joint rigidity will be managed with excessive accuracy.

Cons: Requires entry to each side of joint. A lot of weight in comparison with screws or rivets. Inclined to vibration, particularly if gap hasn’t been reamed to right measurement.

Finest for: Make bolts and nuts your first alternative for any mechanical fastener, then assess whether or not they’re actually what you want or can use in every state of affairs.

Brazing and Soldering

Brazing and soldering are comparable processes. Each be part of metals through media that melts and adheres to adjoining surfaces earlier than solidifying–all with out melting the bottom metals. The excellence is generally considered one of temperature.

Soldering is basically a low-temperature type of brazing. It usually makes use of a filler materials that melts beneath 450 levels, whereas brazing makes use of a fabric that melts above that temperature. Within the case of aluminum, most brazing materials melts round 800-900 levels, which continues to be just a few hundred levels wanting aluminum’s melting level.

Proper off you may see some great benefits of brazing: It’s a non-destructive course of that retains intact the bits that it joins. Consider it as metallic scorching glue, and also you’re heading in the right direction.

Brazing additionally permits dissimilar metals to be joined. Want to stay copper to aluminum? Aluminum to metal? Metal to tungsten? All are potential with brazing, and likelihood is you’ve a chunk of cookware, a bicycle or a firearm that employs a number of such connections.

Consultants will swear up and down {that a} correctly brazed joint is simply as sturdy as the bottom metals it’s becoming a member of, however the phrase “correctly” is doing a lot of heavy lifting in that sentence. Correct brazing–particularly with aluminum–is an extremely finicky course of that requires surgical cleanliness, zero-tolerance becoming, and saintly endurance to realize these strong-as-the-base-metal joints. Not sometimes you’ll find yourself with a blob of brazing rod that simply falls off the joint, cursing on the late-night TV advert for making it look really easy.

Pictures Credit score: Cyfac

Professionals: In a position to be part of dissimilar metals. Requires no instruments extra specialised than a torch. Cheap supplies. Sturdy joints should you do it proper.

Cons: Sturdy joints solely should you do it proper–a lot tougher than it seems on TV. Requires meticulous floor prep and precision to kind finest joints.

Finest for: Non-safety-related fabrications with a number of overlap on the joints, tubing connections, panel bonding, skinny supplies the place welding could possibly be too harmful to the workpiece.

MIG Welding

One of many trickier elements of welding aluminum is its thermal properties. Not like metal, which covers a broad temperature vary because it goes from crimson scorching to gentle to liquid to super-runny liquid melting by way of your shoe, aluminum does all of that inside a way more compressed temperature window. Aluminum additionally absorbs and subsequently sheds warmth a lot quicker than metal, that means the bodily properties of the piece you’re working with truly change throughout the welding course of.

Nowhere is that this extra noticeable than throughout MIG welding. As with metal, MIG welding aluminum employs a filler wire that’s fed into the joint whereas additionally grounding quite a lot of electrical energy, making a highly regarded arc that produces a molten puddle within the workpiece. This molten puddle is moved alongside the joint whereas being fed by the filler wire to kind a welded joint that’s sturdy but, because of the quick fee of cooling, additionally brittle–so not finest for conditions that see quite a lot of vibrations.

Not like with metal, aluminum MIG welding requires pure argon moderately than an argon/CO2 mix, and the softer aluminum wire is normally fed to the welding torch through a spool gun, so the wire doesn’t should push as far. However other than that, the fundamentals of metal and aluminum MIG welding are comparable.

Besides they aren’t. As we talked about earlier than, aluminum’s thermal profile could make MIG welding irritating at instances. As a result of it melts a lot quicker and extra aggressively than metal, your weld beads usually want to maneuver a lot quicker than with metal. So quick, in some instances, that you just actually can’t see into the molten puddle very effectively. So, you should line up your weld, strike your arc, and transfer by way of it with nice precision–totally on muscle reminiscence, since you may’t actually eyeball your method by way of it like you may with slower-melting metal.

Then there’s the truth that aluminum absorbs warmth very quickly throughout the course of, that means your weld move not solely must be fast, it has to speed up. In any other case, the tip of the weld shall be far too scorching in comparison with the start.

MIG welding will be irritating, however when you get the grasp of it, it’s enjoyable and rewarding. And better of all, it may be performed with low-cost MIG machines. Eastwood’s MIG 175 will be ordered with a spool gun for round $500. Swap wires and gasoline, and also you’re welding metal in a couple of minutes.

{Photograph} Courtesy USAF/Elizabeth Baker

Professionals: Low price relative to different welding strategies. Very learnable if you know the way to MIG metal. Quick. A real molecular connection.

Cons: Welding aluminum of dissimilar thicknesses will be capital-T tough. Not the prettiest welds on the earth, even for expert operators. Usually unforgiving relative to metal MIG welding. Brittle joint.

Finest for: Newbie aluminum welders who can adapt their steel-welding abilities to the brand new materials.

TIG Welding

After we consider welded aluminum joints, more often than not we image TIG welds. That stack of completely aligned dimes (or cash of assorted denominations, relying in your talent stage) on the intersection of two items of metallic is an iconic picture, and for good motive: Correct TIG joints are sturdy and sturdy, and even crappy TIG joints are fairly darn good. A bumbling novice with a TIG can in all probability make a stronger joint than a bumbling novice with a MIG, though we don’t suggest entrusting these joints with anybody’s security.

Like MIG welding, TIG welding melts the world on the joint after which permits it to reform after flowing a melting filler into it. However not like MIG, TIG provides you much more management over the quantity and utility level of the warmth going into the joint. With TIG, you strike an arc from the tungsten-tipped torch to the workpieces, then management the amperage–and due to this fact the warmth–of that arc in actual time throughout the welding course of. So, becoming a member of supplies of differing thicknesses turns into a lot simpler, as does working with skinny supplies that might simply be obliterated by a MIG welder.

If it appears like a fancy course of, that’s as a result of it’s. TIG welding requires the operator to take care of the arc with the torch in a single hand, apply filler rod with the opposite, and management the facility with a foot pedal. There’s loads occurring, however the upside is that you just get to regulate the tempo pretty exactly.

{Photograph} Courtesy: USAF/Aaon Jenne

Professionals: Regardless of its complexity, TIG is pretty novice-friendly, principally as a result of it really works in an intuitive method and could be very slow-paced. Makes sturdy, malleable, handsome joints. In a position to be part of supplies of dissimilar thicknesses.

Cons: Dearer than MIG, though costs are coming down and good TIG machines will be had for lower than $1000. Requires quite a lot of consumables. Sluggish, painstaking course of. Irrespective of how good you suppose you might be, there are a whole bunch of individuals on Instagram method higher than you.

Finest for: Initiatives requiring a excessive diploma of precision. Folks with endurance.

Trending Merchandise