[Editor’s Note: This article originally appeared in the June 2000 issue of Grassroots Motorsports as part of our rotary-powered Triumph Spitfire project car. Some information and prices may have changed.]

The Triumph Spitfire’s inventory entrance suspension is well-known in racing circles for being each easy and efficient. Our objective for our rotary-powered Triumph Spitfire was to take these strong fundamentals and enhance them …

Our Unique Entrance Suspension

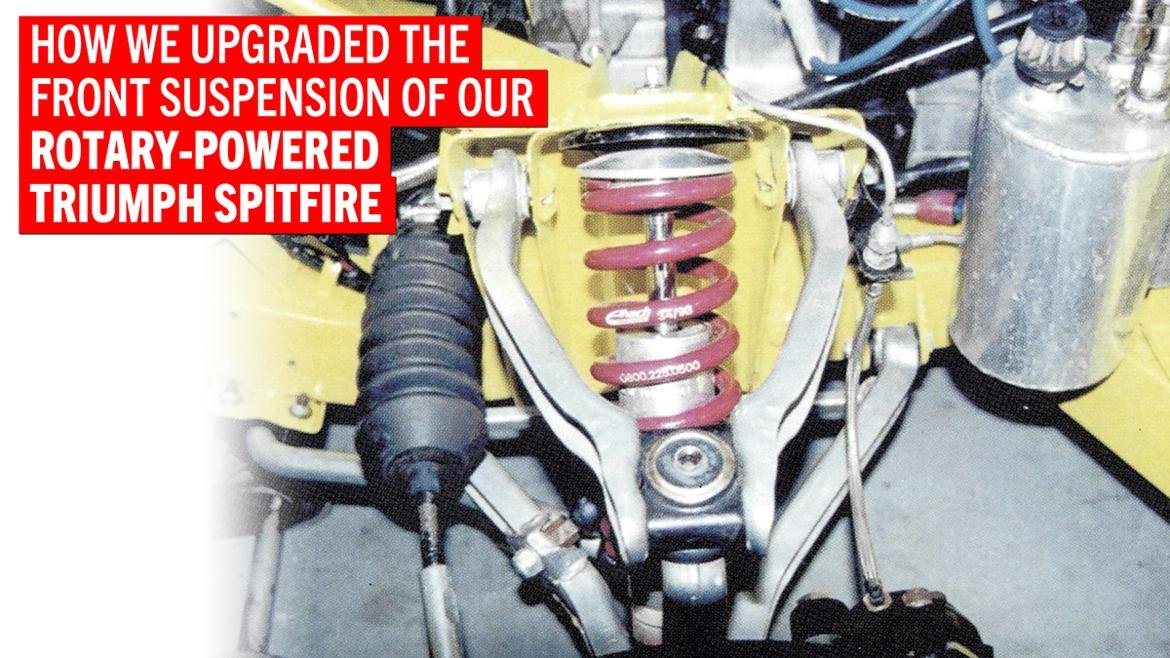

The Triumph Spitfire makes use of a double-wishbone entrance suspension that includes coil springs wrapped round tubular shock absorbers. Whereas adjustable just for toe and camber, this entrance suspension was a preferred design; lots of its elements have been additionally utilized by Lotus, TVR and Elva in addition to different sports activities and race automobile constructors.

Given the inherently sound design of the Spitfire/GT6 entrance suspension, our objective was merely to boost and add adjustability to the unique structure, to not redesign the entire entrance finish of the automobile. To this finish, we took our personal expertise and mixed it with what we discovered after speaking to a number of Spitfire racers.

As we mentioned in our final installment, we upgraded the entrance brakes to bigger GT6 models, utilizing the larger spindles and uprights. Whereas the GT6 items are of practically an identical design to the Spitfire, they do supply bigger spindles, bearings and, after all, brake rotors.

One pretty frequent modification that we didn’t make was to drop the entire entrance finish. Spitfire racers have been identified to chop off the shock towers and lengthen them about an inch, dropping the entrance finish of the automobile and thus reducing the middle of gravity. We aren’t planning to take this automobile to the SCCA Valvoline Runoffs, nevertheless, so we determined that this hardcore modification wouldn’t be definitely worth the effort. Apart from, as you might already haven’t anyticed, we had sufficient work forward of us on this venture.

Our seek for a greater Spitfire entrance suspension led us to TrueChoice, a factory-authorized Koni shock absorber manufacturing facility reconstruct and modification facility. Additionally they are distributors for Eibach Springs.

Selecting the Appropriate Shocks

As we needed adjustability for each shock valving in addition to experience peak (to raised nook weight and decrease the automobile), we selected Koni 8216 collection shocks. This true racing shock features a light-weight alloy physique and exterior rebound adjustment. It should additionally settle for each 2.25- and a pair of.50-inch I.D. springs.

This twin-tube hydraulic design is a cost-effective different to Koni’s costlier double-adjustable 8211 and 8212 collection of shocks (lower than half the value), but nonetheless could be configured for a variety of functions and damping traits.

The 8216 is absolutely rebuildable and comes full with spring {hardware} (for absolutely adjustable coil-overs) and 1/2-inch 1.0. spherical bearings. TrueChoice sells these shocks for $205 every in commonplace lengths and as much as $325 for customized lengths.

On our venture, we ordered the shock constructed to inventory Spitfire size with highway race/autocross valving. We additionally wanted to determine a greater technique to mount the highest of the shock to the inventory Spitfire body.

Whereas the inventory mounting is ample, it doesn’t permit the vary of movement one would love on a race automobile. The parents at TrueChoice made the usage of a brand new high mount attainable by eradicating the inventory spherical bearing from the highest of the shock and changing it with a customized threaded pin mount. This can be a pretty frequent modification that they will make for you, too.

Bushings and Bars

We used polyurethane bushings, obtainable from British Components Northwest, on the entrance A-arms. Additionally they have a whole line of polyurethane bushings for many Triumphs, in addition to selection of different elements.

Our entrance anti-roll bar setup is as uncomplicated as you will get. (It might get extra difficult as we go alongside, however that’s one other story.) We selected an Addeo 7/8-inch entrance alternative anti-roll bar with inventory rubber bushings. (Late-model Spitfires got here with this measurement anti-roll bar from the manufacturing facility, however we did not have a inventory bar obtainable.) On a virtually inventory Spitfire, we usually want a one inch anti-roll bar (additionally obtainable from Addeo), however on our highly-modified Spitfire, we did not really feel we would have liked any extra entrance bar.

Choosing the Proper Coil Springs

Initially we selected Eibach springs, half quantity 0800.225.0350. To know Eibach springs, first you know the way to learn their half numbers. The primary quantity is the free size of the spring, so in our case we’re speaking eight inches. The second quantity is the diameter (2.25 inches), whereas the third is the spring price (350 lbs.fin.).

Nonetheless, as soon as every thing was assembled, the automobile pushed (beneathsteered) like loopy. The specialists at TrueChoice went again to their calculators and mentioned the automobile could not be pushing, as these have been practically optimum spring charges for this utility.

Lastly, the reality got here out: The parents at TrueChoice had misunderstood us, and thought the shock and spring meeting was mounted in a virtually vertical place. In reality, on a Spitfire, the shock/spring mixture is mounted at near 45 levels from vertical. This makes an enormous distinction, as a result of the spring is way much less efficient (and due to this fact must be stiffer) when it isn’t mounted perpendicular to the bottom.

We then mounted 500 lbs./in. springs (Eibach half 0800.225.0500), and solved the issue. We now had a automobile that dealt with practically in addition to it ran.

We are saying “practically” as a result of whereas steady-state cornering was getting into formula-car territory, further testing on a extra bumpy course confirmed us some new issues that we did not encounter on race-track-smooth pavement. We’ll get to them in a bit.

To Win, First You Should Steer

Ah, the knowledge of that age-old adage (okay, we simply made it up). The Triumph Spitfire, like most Triumphs, was blessed with an excellent steering rack. (Once more, many specialty automobile companies–like Lotus and TVR–discovered the Spitfire piece supreme for his or her extra unique vehicles.) Sadly, even the most recent Spithearth is now 20 years previous; so to get essentially the most efficiency out of your authentic steering rack, first you have to to rebuild it.

This rebuild is basically fairly easy–particularly when you let J.Ok. Jackson, who has completed so many he may do them in his sleep, information you thru the method. Primarily, these racks are sturdy, and so long as you do not supply yours from a automobile that has been completely abused or wrapped round a tree, it is best to have the ability to get away with only a easy cleansing, lubrication and correct setting of the preload. This professionalcess is printed in any good store handbook; principally, you have to to rigorously dismantle the rack, examine all of the items, after which put it again collectively. When you’ve got made certain nothing was worn or bent and set the preload per the handbook, you might be able to fly.

As soon as that downside was solved, we acquired prepared to overcome the true enemy: bump steer. Any time you decrease the entrance finish of a Spitfire–or most any automobile–bump steer raises its ugly head. In layman’s phrases, bump steer is when the entrance wheels begin to transfer out and in, thus steering the automobile, when bumps are encountered. Any good suspension system will have the ability to journey all through its vary of motion, whether or not raised or lowered, with out turning the wheels in or out. Nonetheless, drastically lowering any suspension system (even a well-designed one) will trigger the geometry to vary and customarily results in bump steer issues. And as we talked about, one of many causes we selected our new suspension elements was as a result of they provided us the flexibility to regulate experience peak.

With the help of our pal, multi-time autocross champion Man Ankeny, we cycled the Spitfire’s now-lowered entrance suspension by way of its vary of movement and did discover extreme bump steer issues.

The best technique to resolve this, aside from returning the automobile to its inventory experience peak, is to both shim the steering rack or change the place the tie rod ends mount to the steering knuckles. The objective right here is to cut back the severity of the angles–basically, you’d Iike to maintain the tie rods parallel to the bottom and hold the angles they take beneath movement parallel to the angles that the suspension arms or wishbones take beneath that very same movement. Simpler mentioned than completed, proper?

Probably not. It is a fairly easy matter to make aluminum or metal blocks to shim a Spitfire rack up an inch or so. Nonetheless, we went a unique route.

Fairly than have the usual Spitfire ball joints pressed down into the steering knuckles, we drilled out the steering knuckles with a ½-inch drill bit and got here up by way of the underside with heim joints from Aurora Bearing Firm. This setup is lighter, extra direct and stronger.

The one draw back is that, on a avenue automobile, a heim joint does transmit extra noise and vibration than a ball joint. We did not care. We used 1/2×1/2-inch rod ends (Aurora half quantity RAM-8T) and mated them with a threaded sleeve designed for a Crossle Components Ford. These nicely-made items can be found from Don Breslaure at DB Enterprises.

He additionally makes Components Ford entrance hubs (additionally the identical as Spitfire) that match the Dodge Neon entrance brakes fitted to the vehicles used within the Skip Barber Components Dodge Race Collection. Anybody in search of some trick entrance brakes for a Components Ford or Spitfire-based particular ought to examine him out.

These modified heim-joint-derived tie rod ends all however eliminated any bump steer issues we have been having on the entrance of our Ro-Spit. One notice to recollect is that when utilizing heim joints, put washers at both finish in order that in the event that they do in some way fail, they won’t come aside.

The Coat Makes the Man–or Automotive

From the images, it might seem that we chromed nearly each a part of our Spitfire’s entrance finish. Not s9: we acquired every thing coated by Jet-Sizzling. We did not need to use paint as a result of we knew it would not final, but we needed a show-car look with out”the potential weakening of the steel that plating could cause–to not point out the expense and problem.

Enter Jet-Sizzling. We knew their coatings would maintain up, and we knew they have been moderately priced. Nonetheless, up till this venture, we had at all times considered them just for heat-resistant-type functions.

To heck with the warmth. The Jet-Sizzling coatings look superior and have confirmed completely fade- and chip-free on every thing from our header to our rear brake drums (each coated black) to our entrance finish elements (satin silver). The corporate even has a brand new coating that’s reputed to look identical to chrome, We’re going to ship in a single or each of our pesky aluminum BMW bumpers to see if their declare is true.

Future Installments

We now have now lined the main points of our rotary-powered Spitfire venture, from gasoline supply to physique work. However, we nonetheless have a number of particulars to wrap up, together with our new coil-over rear suspension. Search for extra on this matter in an upcoming situation.

Trending Merchandise