First step to utilizing carbon fiber? Whether or not constructing new components or fixing damaged ones, it is advisable to begin with the appropriate kind–and meaning understanding weave kind.

A carbon-fiber weave refers to how the bundles of carbon fibers, often called tows, are woven collectively to create sheets. Every weave has completely different properties and advantages.

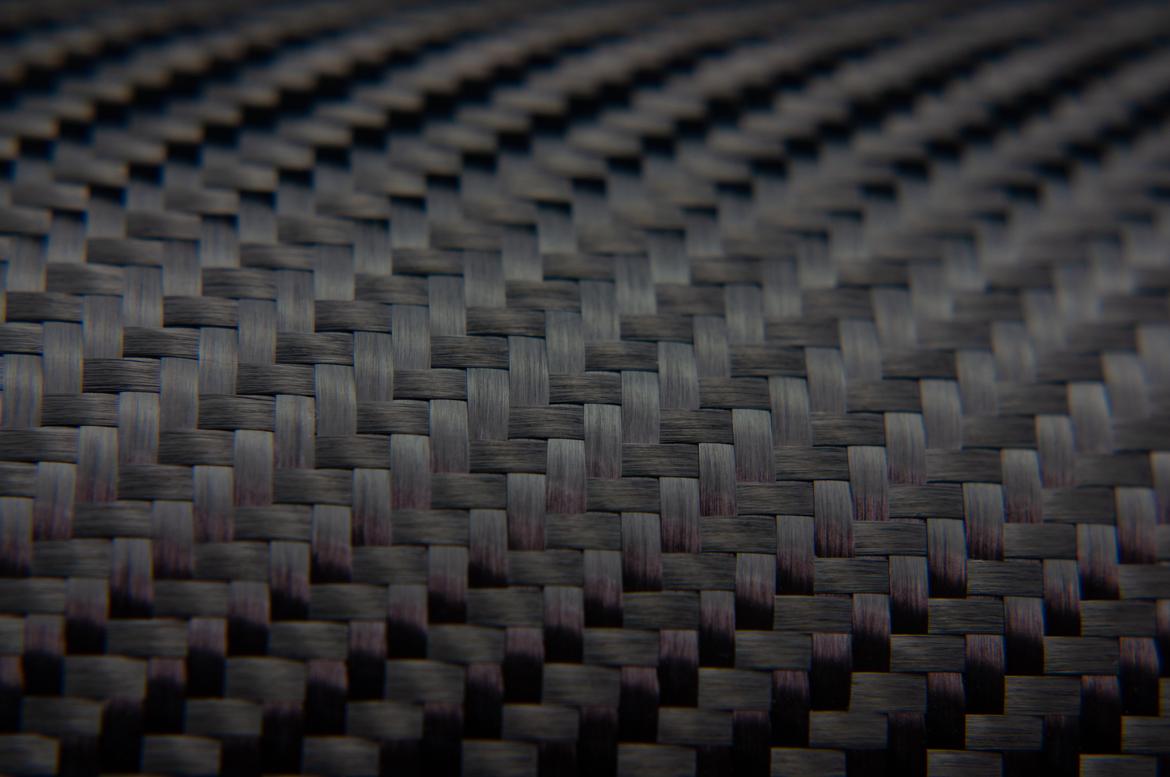

Plain Weave

Does your mission lack complicated curves however want excessive stability–like repairing a door or creating aero panels? Plain weave might be the way in which to go.

Its easy over-under tow sample–woven like a basket–offers excessive stability, straightforward draping and uniform energy distribution. Nevertheless, it’s not greatest suited to areas which have complicated curves–image making an attempt to mould a bit of card inventory round a ball.

Twill or Satin Weave

If complexity is what you want, think about using twill weave or satin weave. Though twill weave encompasses a related over-under theme, it makes use of a diagonal sample. This sample encompasses a single horizontal tow of carbon, often called a weft path, alternating over and underneath two or three of the first vertical structural tows, often called a warp path.

Because of this diagonal interlocking, twill weave provides greater sturdiness, higher drapability and better visible attraction. The downsides? Decrease stability, lowered stiffness and elevated value. This is the reason most twill weave is used for items that have to be mild and robust–so physique panels, splitters or suspension elements.

Harness-Satin Weave

The third commonest weave sample is harness-satin weave. Whereas much like plain weave, this kind has lengthy float lengths–which means the weft tow passes over a number of warp tows with out interlacing, typically at 4, 5 and eight intervals, often called 4HS, 5HS and 8HS.

These floats create a smoother, nearly shiny floor end. 8HS weave permits for some of the versatile buildings for complicated geometry and improved load switch.

The downsides? Satin weave isn’t simply tough to work with as a result of it’s susceptible to snagging and fraying. It’s additionally dearer and provides much less stability in a number of instructions–therefore why you’ll see it in additional inside element tasks.

Unidirectional vs. Bidrectional vs. Multidirectional Weaves

Unidirectional carbon weave is much less of a weave. Fairly, it’s when all of the fibers are oriented in the identical path, therefore, unidirectional. Challenge-wise, such a weave needs to be used when the load forces come from one path.

That’s proper, carbon weave is additional sophisticated with fiber orientation–the path by which the fibers level.

Plain, twill and harness-satin weaves are usually woven with fibers oriented at 90 levels to 1 one other, often called bidirectional.

In the meantime, extra complicated patterns, the place structural parts run in three or extra instructions, supply enhanced load capabilities and are often called multidirectional.

In the long run, the extra complicated the weave sample, the stronger your ultimate product will likely be. However remember that will probably be dearer and susceptible to falling aside throughout dealing with.

Trending Merchandise