[Editor’s Note: This article originally appeared in the May 2008 issue of Grassroots Motorsports.]

By no means underestimate the facility of a plan, significantly in competitors. Each crew that competes in our $200X Problem occasions does so with a point of premeditated intent. One peek on the Spotter’s Information reveals that the complexity of those schemes varies enormously from one crew to one other.

For some, the sport plan consists merely of discovering an inexpensive automotive, placing some low cost components on it, and having a blast on the occasion. Means on the different finish of the spectrum are the grandiose machinations dreamed up at 2 a.m. after one too many beers. These difficult tasks generally find yourself as barely operational metallic abominations or hilarious, long-term storage artwork.

There’s a candy spot, nevertheless. We’ve seen that the highest finishers at our low-buck Challenges usually begin with a strong, practical plan and do their finest to stay to it.

Contemplating the tight price range at a $200X Problem, a substantial amount of flexibility is usually required within the execution section. Nonetheless, the nearer the top result’s to the preliminary idea, the higher. Like an expert photographer composing the shot in his thoughts earlier than he triggers the shutter, masterpieces are the results of foresight, strong technical ability, and a measure of good fortune.

Guide Smarts

Ultimately October’s Kumho Tires Grassroots Motorsports $2007 Problem introduced by eBay Motors and CDOC, a lot of the Challengers confirmed up the Thursday earlier than the occasion to register and to show of their construct books. These books usually comprise photos of the crew’s construct, together with receipts and spreadsheets detailing the price range. Some go so far as to incorporate backstories and construct diaries.

Construct books are available in very helpful once we’re writing in regards to the vehicles for the journal, however to be trustworthy, registration is a busy scene. With the road backing up, we’re extra fearful about getting everybody the best wristbands than we’re about flipping by way of the construct books. Because of this, the books have to attend till Friday for evaluation.

In a means, placing them apart preserved the amazement we loved when Group Cheaparral rolled their No. 66 Corvette off its trailer on Friday morning. Along with the standard collage of receipts and pictures, the Cheaparral construct e book was stuffed with atypical entries that might have spoiled the shock.

For instance, there was a really skilled spreadsheet with 12 potential engine choices for the V8, starting from carbureted with nitrous injection to twin-superchargers, full with estimated horsepower figures, prices, quarter-mile instances and efforts required. A number of of the pages had been dedicated to defining the duty leaders, members and schedules for no fewer than 9 challenge subteams; an area shuttle launch can’t be rather more difficult than this.

Then there was the occasional math-heavy web page full with titles like “Estimate Fan Necessities for Zero Velocity Downforce System.” Precisely what sort of challenge was this, anyway?

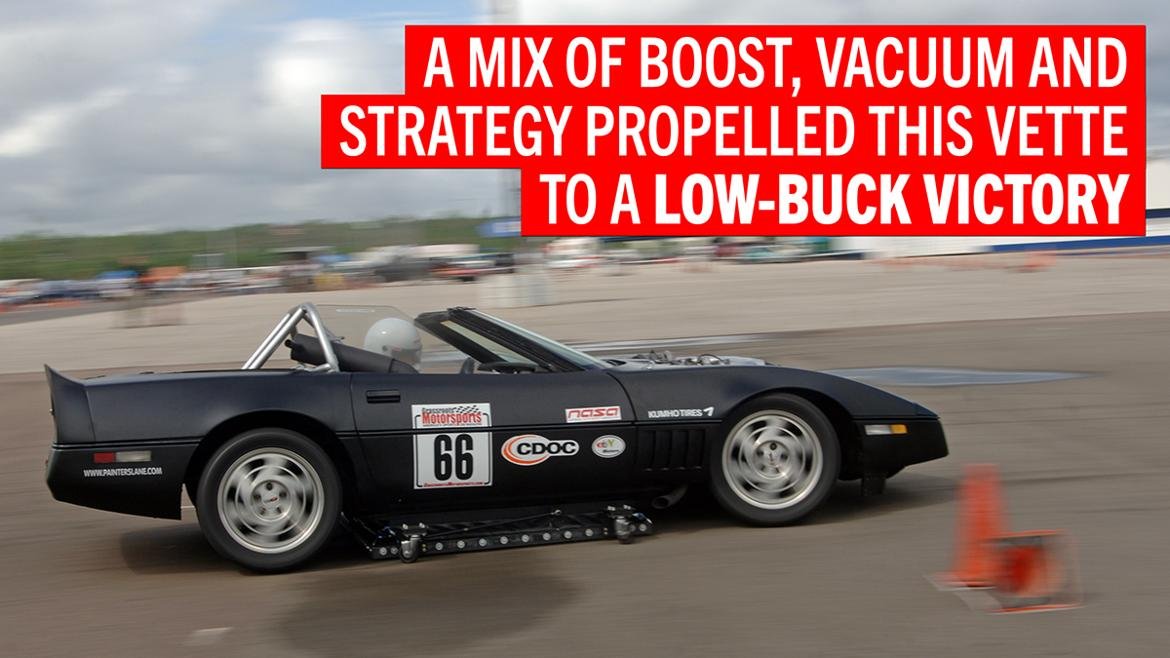

Within the easiest phrases, the Cheaparral 2J-2 is a 1986 Chevrolet Corvette powered by a twin-turbo V8 and modified with a particular undertray able to producing 1000 kilos of vacuum downforce at any velocity—the identify Cheaparral being an homage to Jim Corridor’s well-known Chaparral 2J sucker automotive. The Cheaparral dominated on the autocross and blew the decide’s minds within the concours, and the entire enchilada was constructed for simply $1920.70.

A Design for Victory

The Cheaparral crew clearly spent a ton of time on this challenge even earlier than they’d a automotive to wrench on, however the effort was not an irregular stretch for crew chief Stoyan Lokar and the dozen or so fellow Procter & Gamble engineers who contributed to the challenge. For them, the Cheaparral was a solution to have enjoyable and do some crew constructing whereas flexing their motorsports muscle.

“We develop machines that make P&G merchandise like Tide, Crest, Pringles and Duracell batteries,” Stoyan explains. “We do quite a lot of various things. We talked about all of the build-off reveals on TV, and we mentioned, ‘Hey, we may do one thing like that.’”

Whereas the crew was nonetheless brainstorming about the kind of challenge they’d love to do, one of many crew members introduced the GRM Problem to their consideration. Very quickly, the Problem was close to the highest of the spreadsheet itemizing potential motorsports tasks.

The largest draw of the Problem was the competitors side. “Not solely would we get to construct one thing, however [we would be] evaluating it to different folks doing the identical factor,” displays Stoyan.

The crew in the end had to decide on between constructing an Ariel Atom-type bare automotive or a $2007 Problem automotive; their Automotive Undertaking Determination Evaluation sheet reveals the Problem successful by a 13 % margin. (Critically, we’re not kidding about all of the spreadsheets and tables.)

With their course set, the crew dug in and began their $2007 Problem challenge in earnest. Er, that’s to say, they did extra analysis. First, they compiled a desk of the highest, center and backside percentile performers from earlier Problem occasions. Utilizing this data, they got here up with goal scores for the autocross, drag and concours segments that they felt would end in a victory.

Armed with a selected purpose, the crew began attempting to find vehicles on eBay and within the native classifieds. They contemplated every thing from the BMW 2002 to extra normal Problem fare just like the Mazda RX-7 and Porsche 944.

Lightning struck after they noticed a rolled, salvage title 1986 Chevy Corvette within the Tradin’ Submit classifieds for $2000. As a bonus, the Vette was not removed from the crew’s house base in Cincinnati, Ohio.

“The Corvette was in all probability the eighth or ninth automotive that we ended up ,” Stoyan remembers. “It was already February. We realized we would have liked to get the automotive pretty shortly. The physique was in horrible form, however the engine was intact and it began proper up. We had been in a position to negotiate on the value—the man’s spouse actually wished to get it out of the barn. He got here all the way down to $1400 finally.”

At this level within the story, it’s apparent that the Cheaparral crew can kick butt with spreadsheets and planning. Nonetheless, it’s simple to imagine that they could falter when confronted with the chilly metal of a bodily construct, significantly one as advanced as this Vette. Because it seems, these Procter & Gamble wrenchers are good with loopy concepts, however they excel at bringing them to life. Gaining access to industrial-grade designing and machining instruments doesn’t harm, in fact.

It’s Solely Loopy Till It Works

With the closely broken Corvette within the store, the crew had about six months to execute the remaining 5 phases of their multistep construct schedule. The plan would take them from disassembly and cleansing by way of remaining testing after which all the way down to Florida for the Problem. Alongside the way in which, every crew member had numerous duties to maintain the challenge on monitor.

It took about six weeks simply to get the automotive operating and repaired effectively sufficient to acquire a title and registration. As soon as the wheel bearings, A and B pillars, windshield, lights, and jagged physique had been addressed, the challenge moved into the modification section.

“We had been specializing in three most important areas,” says Stoyan. “One was how we’d get extra energy—that [Corvette] engine was a canine that yr. Second, how can we eliminate quite a lot of weight? And third, how can we enhance dealing with?”

An untold fourth class—one which we see on quite a lot of Problem vehicles—was to implement one thing that might make each crew member chuckle a bit after they noticed it. For Group Cheaparral, the thought got here to them as they completed off a pony keg of Blue Moon Belgian White ale. Not coincidentally, that exact same pony keg was below the knife very quickly, and it might serve from that time ahead as a gasoline cell and a punch line for his or her creation.

For energy, the crew hoped to enhance the peaky torque curve of their early injected C4 Corvette. After going over a dozen engine choices, the crew settled on the comparatively cheap however advanced twin turbocharger choice.

“We picked the small Garrett T25 off Mitsubishis,” Stoyan explains. “They’re very low cost since everyone seems to be buying and selling them out for greater ones. They had been spinning up instantaneously—as quickly as you hit the pedal they’re proper there.” The turbos ended up costing simply $71 for the pair.

It took a little bit of trial and error to get the oil strain for the turbos good, and within the course of they fried one of many generators, breaking its shaft in half. Thankfully, no fragments went into the engine, and so they had loads of time to supply and set up a alternative.

The crew made their very own turnbuckle-adjustable wastegates and settled on 6 psi of increase. They figured this strain was a tad dangerous contemplating the forged pistons, however nonetheless doable. They anticipated the setup to web them greater than 300 horsepower on the inventory internals at a low 4000 rpm redline. Torque from the massive, turbocharged engine was not going to be an issue.

Decreasing the mass of the Corvette was pretty simple as compared. The crew did it the old style means, merely eradicating something that wasn’t obligatory for the competitors. Since taking the automotive aside and cleansing every thing was an early step of their plan, it was merely a matter of not placing the heavy bits again in. This allowed them to maintain the aggressive weight proper round 3000 kilos in autocross trim, or 2800 kilos in drag trim.

That 200-pound distinction is the kicker. It accounts for the Cheaparral’s secret weapon, an ingenious, low-buck, vacuum-generated downforce meeting.

It Sucks (In a Good Means)

“For the dealing with, we had been all the standard issues, like suspension and floor results,” Stoyan remembers. The crew realized that they couldn’t generate sufficient velocity at an autocross to make the standard aerodynamic aids price their value or complexity.

“Then we thought, ‘Didn’t Chaparral do one thing with a blower?’” Stoyan remembers. “One of many engineers, Cliff [Papsdorf], began performing some calculations to get numerous g numbers. It seemed prefer it was doable.” The crew hung out modeling the airflow after which constructed a take a look at mule for proof of idea.

“We received some industrial blowers that we use for numerous machines, attached a five-foot-diameter blower with a 50-horsepower motor, and did some exams to see how near the bottom it needed to be and what sort of drive was wanted,” he explains. “We knew it was possible, however we had to determine methods to get it right into a automotive.” Discovering a compact however highly effective blower inside the allotted price range was the largest problem the crew confronted.

“We at one level considered constructing our personal blower, however because the chief I used to be saying, ‘No means in hell.’ The clock was ticking,” Stoyan remembers. They had been per week away from giving up on the thought when Cliff, prowling the Web late at evening, discovered their answer in an surprising place—the again of an M1 Abrams most important battle tank.

“He discovered this tank exhaust blower being offered for scrap metallic surplus,” Stoyan remembers with a smile. “He referred to as the corporate that builds the blowers to get some fan curves and he finally ends up speaking to the engineer who designed it.”

Amazingly, this compact, high-flow, light-weight alloy vane-axial, two-stage fan value the crew simply $26.50. “I’m positive the federal government pays dearly for these. We principally picked it up for the scrap metallic worth. It had met its service lifetime.”

The blower was removed from pristine, nevertheless. The crew suspects it had seen obligation in Desert Storm, because the unit was full of sand and usually in tough form. They polished the vanes, rebuilt the bearings and did their finest to deal with galling on the shaft. Stoyan estimates that 20 man-hours went into refurbishing the blower.

Utilizing computer-aided design packages, Cliff and the others got here up with plans for the under-car skirt design and methods to mate the blower to a used snowmobile engine. The blower is pretty unique, however the remainder of the meeting is primarily manufactured from plywood and off-the-shelf {hardware}, like casters. These extra mundane parts had the essential obligation of holding the entire meeting rolling and stopping it from sucking itself fully to the bottom.

In operation, the setup is surprisingly easy. An enormous sq. tray is hooked up to the underside of the automotive with a easy suspension. The tray rides on casters that preserve it the best distance off the bottom for the goal vacuum, and a versatile skirt creates the hermetic seal between the tray and the underside of the Vette.

When the blower is activated, air is sucked out of the tray’s cavity, making a area of decreased strain between the automotive and the bottom. Because of the vacuum, the underside of the automotive needs desperately to comfortable as much as the asphalt.

At an operational vacuum of 10.0 inches of water, the Cheaparral’s sucker design yields an superior 1000 kilos of downforce with an inertial penalty of simply 200 kilos of {hardware}. The entire system may be eliminated or put in on the monitor in about an hour.

When a Plan Comes Collectively

There have to be one thing to all these schedules, tables, spreadsheets and charts, as a result of Group Cheaparral was in a position to full their challenge on time and below price range. “We had been primarily full about two and a half weeks earlier than the race,” Stoyan says. “We had been in a position to get a few weekends to present Danny [Popp] some seat time.”

From the second the Cheaparral rolled off the trailer and folks realized what the undertray was for, the automotive was surrounded by Challengers poring over its secrets and techniques. The concours judges took word of the engineering genius, in addition to the match and end of the construct, and awarded it first place within the concours. And when the Vette pulled as much as the road for its first autocross run, all ears perked up on the unmistakable high-pitched whine of the snowmobile engine driving the tank blower.

A 30-foot twister of sand and particles shot up from the passenger-side blower as driver Danny Popp muscled the Cheaparral to a 33.208-second time—good for quickest time of the day—on his very first run on the autocross. Sadly, a touch screw had shaken unfastened on the bumpy trailer journey down from Ohio and located its means into the throttle pedal pivot. This brought about the throttle to stay, which botched the automotive’s second and third runs. The blower motor lower out on the ultimate run, however the crew had earned sufficient factors to take the general $2007 Problem victory.

Not surprisingly, the general challenge’s six-phase time chart in Group Cheaparral’s construct e book already had small blocks of time put aside for a “victorious return” and “Company Engineering Expertise Lab celebration” within the two days following the $2007 Problem. Speak about sticking to the plan.

The Cheaparral Offers Again

From the very begin, Group Cheaparral wished the top results of their challenge to profit charity. To realize this purpose, they anticipated auctioning off the ultimate consequence or promoting it to a museum and giving the proceeds to a neighborhood trigger. That’s nonetheless the eventual plan, however within the meantime their radical sucker Vette goes to be a trainer, too.

“We’re going to a neighborhood college to speak to the scholars in regards to the physics that went into the sucker system, to elucidate what centripetal drive is, what friction is—convey what they’re studying at school to a real-world instance,” says crew chief Stoyan Lokar. “The trainer thinks the youngsters are gonna eat that up as a result of it’s such a cool-looking automotive. It’s a goodwill ambassador to encourage others to make use of inventive science.”

On the Wheel

Should you’ve been studying GRM for some time, you’re in all probability acquainted with the identify Danny Popp. Again in June 2004 we featured his A Avenue Ready-winning Z06 Corvette, and extra lately Popp took a primary at school and second total—simply behind Tommy Archer—in our 2007 Final Observe Automotive Problem.

Popp was really pondering the opportunity of a C4 Corvette for a $200X Problem when he was contacted by Cliff Papsdorf, one of many Cheaparral engineers, to seek the advice of on their very own $2007 Problem Corvette. When Cliff defined that they had been going to aim to make the Vette a sucker automotive just like the Chaparral 2J, Danny determined they had been a bunch of loons.

“I used to be proper,” laughs Danny, “they definitely are loons, however they’re very progressive loons.”

When the construct was nearing completion, Danny was invited to check drive the automotive. “It was considerably later at evening than we had deliberate, so we may now not arrange an autocross within the lot. However we may arrange a skidpad.” One 250-foot diameter skidpad later, Danny put in some baseline runs with out assistance from the blower. “I used to be fairly happy. [The car was] a little bit unfastened however nonetheless good.”

Then it was time to strive the skidpad with the sucker motor on. “Cliff fired up the snowmobile motor and I used to be in sensory shock,” Danny remembers. “That factor was loud. The one factor you possibly can hear was the [snowmobile] motor operating—it made shifting by ear unimaginable.”

What the system lacked in NVH consolation, it made up for in efficiency, slicing 1.5 seconds—about 10 %—from the skidpad lap time. “Unbelievable. I’ve by no means seen something prefer it,” Popp says.

Three days later they arrange a 30-second autocross course. “My dad introduced his B Avenue Ready Corvette over to baseline the automotive towards—LT4, six-speed, 315s up entrance and 335s within the rear. Quick,” Danny explains. With out the sucker motor, the Cheaparral was about 1.6 seconds behind the BSP Vette. With the fan operating, the Cheaparral bested the race automotive by 1.4 seconds, which means the blower was price about 3 seconds—10 %—on the quick autocross.

So what’s it wish to drive a vacuum-assisted twin-turbo Corvette?

“I needed to drive off really feel solely. There’s no noise apart from the sucker,” Danny says. “It took a while to get used to only how succesful the automotive was for a beater automotive. The largest space of enchancment was clearly dealing with—the braking potential was by no means realized on the speeds we had been touring. Acceleration was not harmed in any respect.”

The one aspect that was negatively affected was the facility steering, he continues. “It was marginal to begin with, and it didn’t like the extra 1000 kilos of downforce. It was not linear, both. These are the sorts of surprises that you simply don’t like, however there was no cash within the price range to repair it.”

Popp insists that little snags just like the unfastened screw within the throttle pedal prevented an illustration of the Cheaparral’s true dealing with potential. “There was extra—much more,” Popp assures us. “No less than two extra seconds on the autocross course.” Contemplating Popp’s stage of expertise, the bizarre grip stage of the automotive and the truth that he set FTD on his first run, we’re inclined to consider him. “Possibly subsequent yr,” he grins.

Trending Merchandise