There comes a time in each fabricator’s life after they notice there’s an asymptote within the dwelling storage. Irrespective of how expert you’re with a grinder, how straight your hacksaw cuts, or how regular you possibly can maintain that hand drill, there’s an invisible line of high quality and accuracy that you could strategy–however by no means cross–at dwelling.

We’re speaking about these brackets in your race automotive which are clearly handmade, or the fabricated elements with extra proper angles and grinder marks than each different element in your BMW mixed.

These flaws add character to any construct, and so they’re a badge of honor for a lot of fans. However they’re additionally proof of your limitations, indicators that there’s an entire new world simply over the horizon.

We’re speaking, after all, concerning the world of machining, the place tolerances are measured within the tenths of a thousandth of an inch, and the chances are seemingly limitless.

Most fans have restricted expertise on this courageous new world. Possibly you’ve splurged for just a few shiny billet elements or pushed over to your native machinist and requested for assist. However these strategies are sometimes wildly costly, and also you’ll discover most machine retailers don’t actually wish to make a single half in your race automotive; they’d fairly make 1000 elements in your enterprise.

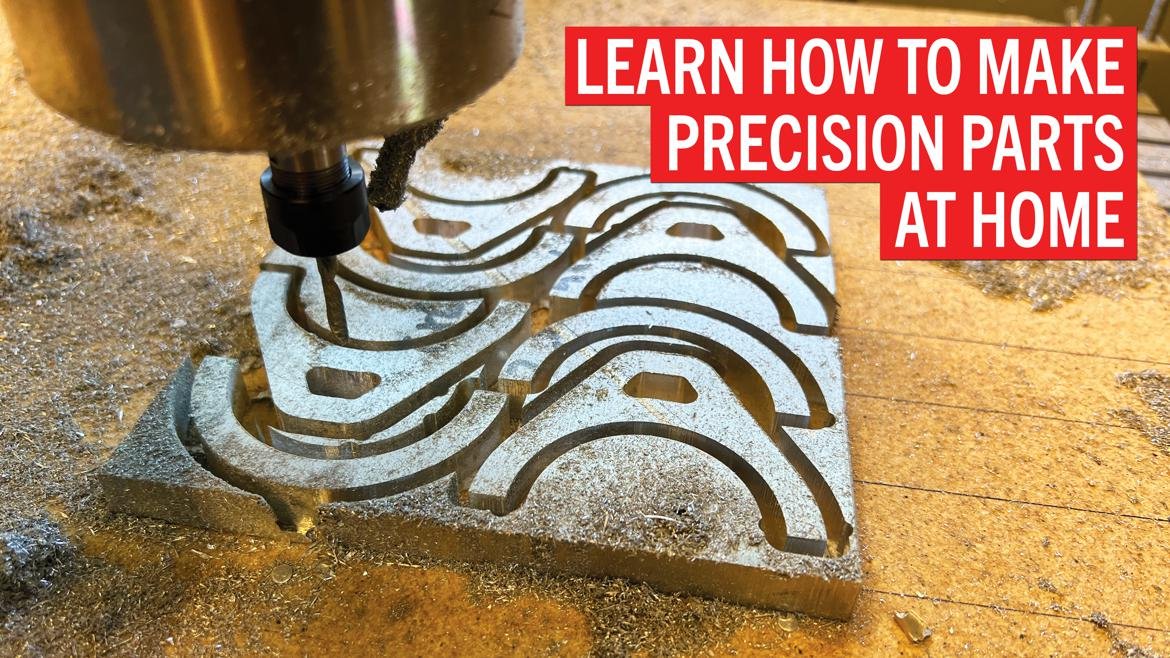

We discovered our personal limitations when turning our LS-swapped 350Z from a road automotive right into a observe automotive. We shortly realized that perfecting our grinder approach or measuring increasingly more fastidiously nonetheless wouldn’t lead to fantastically machined elements like those discovered within the automotive’s LOJ Conversions swap equipment.

Visiting LOJ’s store put the considered machining into our heads, and watching This Old Tony on YouTube fixed it there firmly. We wished to study the black artwork of machining, and we had been prepared to fall all the way in which down the rabbit gap to do it.

However we’re not going to go to commerce college, give up our day job, or pay the value of a good home to study this ability and purchase the gear to observe it. Over the following few points, we’ll clarify how we realized to make constant, correct, advanced race automotive elements in our dwelling storage–all on a price range with far fewer zeros than you’d anticipate.

We’re not specialists and possibly by no means might be. We’re nonetheless new at this. We’re in all probability doing a few of this fallacious. Actual engineers and machinists will in all probability write us letters with recommendation we must always have heeded earlier than we began. None of that’s going to cease us, although. Let’s go.

Drafting: Not Only for NASCAR and Horses

Each new ability has a language and rituals. Machining isn’t any totally different. Earlier than we purchased a mill or turned on a lathe, we would have liked to vary our workflow. Welcome to the world of drafting, additionally known as technical drawing. This course of is the bedrock of creating stuff with accuracy.

We’ll pause briefly right here and apologize for our language: A lot of what we’ll be speaking about on this collection isn’t technically machining. We’re utilizing that time period, lengthy the holy grail for us and different racers, as shorthand for the concept of planning elements all the way down to the smallest element, then constructing them to these plans precisely.

It’s the distinction between taking 5 photographs at that new alternator mount with just a few hunks of metal plate and a grinder versus measuring, planning after which machining that alternator mount to suit appropriately the primary time. The advantages are apparent: You’ll construct quicker, throw much less materials within the scrap bin, and get a nicer completed product.

So, technical drawing or drafting: Wikipedia describes it as “the act and self-discipline of composing drawings that visually talk how one thing features or is constructed.” And, properly, yeah, that just about covers it.

At the moment, you don’t even want to select up a pencil. Autodesk’s Fusion 360, a free program, brings computer-aided design to the lots. How do two elements work together? This system can present you.

You’ve in all probability already achieved some drafting, even when you didn’t understand it. Ever wanted to make a tab, then drew a sq. and a circle on a chunk of scrap cardboard with the diameter labeled so that you wouldn’t overlook which dimension drill bit to seize? Congratulations, you possibly can add “technical drawing” to your resumé.

Why is that this vital? As a result of there’s a line to acknowledge right here: Not all machinists are engineers, and never all engineers are machinists. In truth, most are just one or the opposite. They don’t talk with one another in English (an exceedingly uncommon ability for engineers). Nor do they use hand indicators, Morse code or interpretive dance.

The one language engineers and machinists share, and the one you’ll have to study, is the technical drawing. These are how the engineers clarify to the machinists what they should make, and the way the machinists clarify to the engineers that they’ve designed one thing unimaginable to construct with out breaking the legal guidelines of physics.

In the event you’re going to construct race automotive elements in your storage, you’ll have to grow to be each an engineer and a machinist, so let’s begin in the beginning.

Engineering: Good in Metallic, Nice on Paper

If you may make a bracket, you’re already an engineer–simply on a smaller scale than those at SpaceX. Engineering mainly means utilizing science to design stuff.

In the event you’re like us, although, you didn’t sit down with a chunk of paper and a pen to determine precisely what dimension and form your bracket must be upfront. You simply went to work, utilizing extra artwork than science and letting the piece of scrap metallic you grabbed dictate the bracket’s closing type.

There’s nothing fallacious with that. However we encountered an enormous paradigm shift as quickly as we began enthusiastic about the drawing as an alternative of simply the completed half.

Slightly than simply begin constructing, take just a few additional minutes to sketch out the bracket’s form on a chunk of paper. Subsequent, add the size of every line, together with the situation and dimension of any holes you’ll have to drill. Yay, you’ve simply completed your first actual technical drawing.

By making a technical drawing and translating your bracket into the common language of creating stuff, you’ve unlocked an entire new world. Now, it doesn’t must be you who makes that bracket. Your buddy might make it for you. Or the native machine store. Otherwise you in 5 years whenever you break the primary one in a tire wall and may’t bear in mind what it regarded like.

Technical drawings and engineering are inextricably linked, and we’ve discovered they pressure you to resolve issues, like an interference or an unsupported axis, on paper as an alternative of after making a component. Conversely, drawings can even show you how to fill within the blanks by letting you math your method to required dimensions as an alternative of simply guessing whenever you’re standing in entrance of the bandsaw.

Parametric Design and You

Earlier than we go any additional, there’s yet another idea to grasp: parametric design. Wikipedia has an elevator speech for this, too: “Parametric design is a paradigm in design the place the connection between parts is used to govern and inform the design of advanced geometries and buildings.” We did warn you that engineers don’t do properly with English….

Right here’s our try at an evidence: Parametric design is the concept that a design is definitely only a assortment of traces and constraints, and so they mix to make difficult elements.

Take a sq. as a simplified instance: A standard drawing would specific “There’s a sq..” A parametric drawing, although, would say “There are 4 traces, every of equal size, with coincident factors at every finish and a 90-degree angle at one nook.” Add a dimension to a type of traces–say 2 inches–and since the design is constrained right into a sq., the opposite traces should be 2 inches lengthy, too.

Take this a step additional and alter the sq. right into a dice. Once more, a traditional drawing would simply specific “There’s a dice.”

Our parametric drawing, although, creates that dice by saying the sq. we’ve already constrained is extruded right into a stable object with an equal peak to the size of the traces within the sq.. Besides, darn, we’ve by chance drawn our sq. too small. What occurs once we return and alter that 2-inch line to a 3-inch line? Magically, the dice now measures 3 inches on all sides. Our parametric constraints have dictated every factor’s relationship to the one which got here earlier than it, fairly than an absolute form, which means our design is straightforward to switch and so as to add growing ranges of complication on prime of.

Parametric design is the usual for many CAD packages, and although it may be intimidating at first, you’ll quickly come to adore it.

CAD: Time to Let It Out of the Bag

Drafting that parametric design with a paper and pencil is a ache, proper? We tried it roughly twice earlier than utilizing up the eraser and spilling espresso throughout our technical drawing. There needs to be a greater means and, shock, it’s computer systems.

Pc-aided design software program is extra accessible than it’s ever been, and there’s no cause to not use it. There’s in all probability a highschool drafting instructor someplace who will cancel their subscription after they learn this, however we’ll say it anyway: Transfer to CAD as quickly as you presumably can and by no means look again.

Don’t imagine us? How’s this for an anecdote: We downloaded Autodesk Fusion 360 onto our 8-year-old pc, binge-watched some YouTube tutorials, and had an understanding of how to attract easy elements after one night.

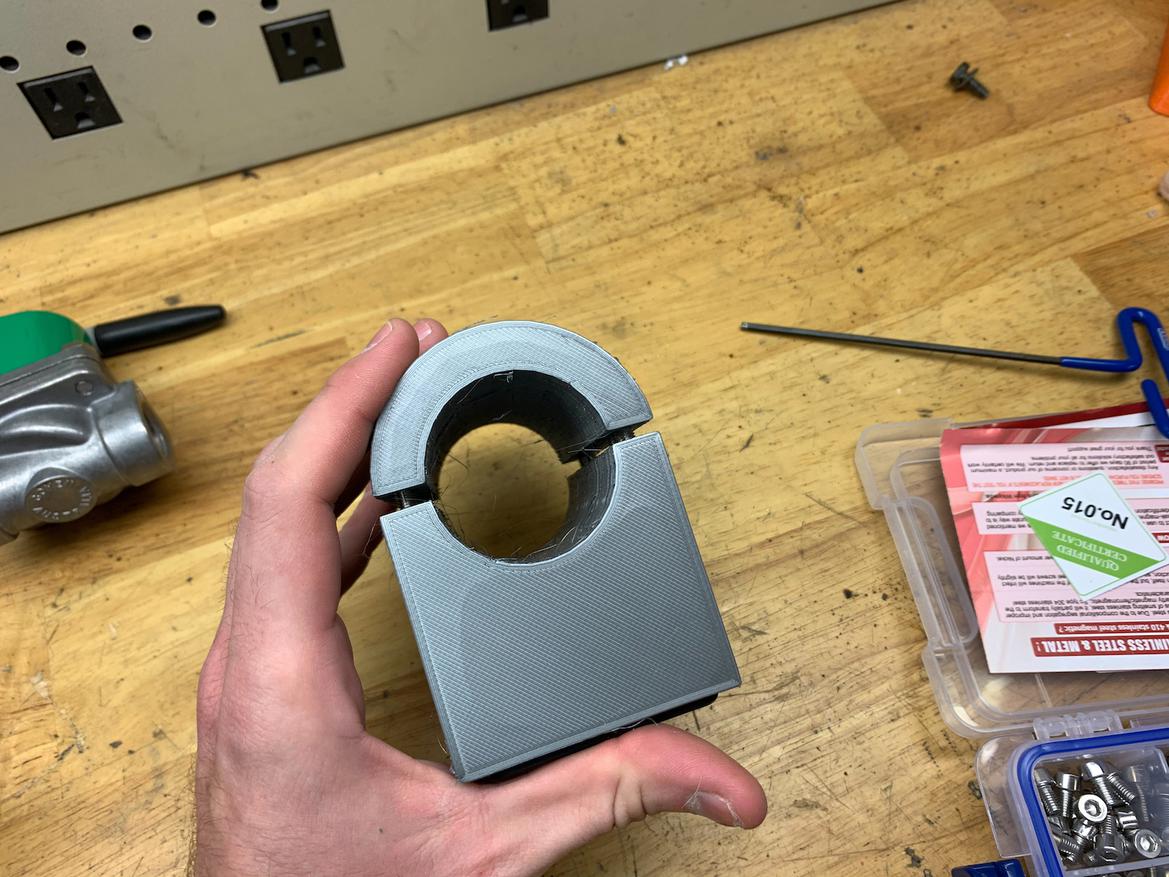

We used Fusion 360 to design this mount for a hearth suppression system’s management field. It’ll mount to our 350Z’s roll cage, and why zip-tie the unit in place when a extra elegant resolution is feasible? After inputting the fundamental parameters, we labored on the precise design–no prototypes, no wasted materials.

After just a few months, we will draw extra difficult elements than we will determine the way to make on a three-axis mill. Yeah, the times of needing a pc science diploma to make use of CAD are over. Fusion 360 is free for hobbyists and has each function you’d ever need in a house storage, however there are a number of nice options, too.

Simply do what we did and determine what your pals are utilizing, then obtain that software program. No pals? Don’t fear: The web is filled with tutorials, and so they’ll do a much better job explaining the main points than we might.

Engineering on the Pc vs. the Workbench

Now that you simply perceive what drafting is, why it’s vital, how parametric design works, and the way to make a parametric drawing, it’s time to get fancy. You’ve in all probability barely progressed past the flexibility to attract cubes and cylinders on the pc, however that doesn’t imply you possibly can’t begin engineering in a digital setting.

We spent night after night simply taking part in round on the pc, realizing that what was engineering brick partitions–like precisely the way to join two elements to one another–are literally simply alternatives.

Slightly than draw the difficult bracket, we discovered ourselves drawing each elements it wanted to bolt collectively, drawing the metallic inventory we’d be constructing the bracket from, then smashing them collectively within the digital world to let the pc determine the place we’d have to clearance issues and the place we had been lacking materials.

It’s a troublesome idea to clarify in a paragraph, however engineering in a CAD drawing is like having X-ray imaginative and prescient, superhuman calculator skills and a photographic reminiscence unexpectedly, and we’ll by no means return to looking at soiled elements on the bench once more. The perfect instructor right here appears to be observe, and each useless finish might be solved by Googling the identify of your CAD software program adopted by the impact you’re attempting to attain.

And when you make a mistake? You’ve wasted nothing however time, and it’s simple to scroll backward within the timeline and make one other try at it.

From Your Laptop computer to Actual Life

Now that you simply’re engineering on the pc, you’re in all probability taking a look at pictures of gorgeous three-dimensional elements which are so shut but to this point. You may spin them round on display screen along with your mouse, and even bolt them along with the identical keyboard you employ for Fb rants.

However you possibly can’t contact them. Sadly, there’s no Management-P for bodily elements. (Properly, there form of is, however we’ll cowl that within the subsequent installment of this collection.)

Bear in mind Wikipedia’s drafting definition from the start of this story? It’s time to create a chunk of paper that reveals a machinist the way to make what you’ve simply engineered in your PC.

Fortuitously, that is fairly simple. Most CAD packages can generate these drawings nearly mechanically, and after some tinkering you’ll be capable of print just a few totally different views of your half with the required dimensions labeled.

It’s exceedingly vital to place your required tolerances on the drawing, too: Can one thing be just a few 1000’s off and nonetheless perform? Okay, by which route? Larger? Smaller? Neither? The topic of tolerances is past the scope of this text, however no respected machinist will make one thing for you with out understanding the margin of error they must work with.

Technique to go: You’ve engineered a component, designed it on a pc, and created visible directions so any person could make it for you. Now you simply want to seek out that any person.

Welcome to the long run: We 3D-printed our mount proper in our personal store. We’ll element that course of within the subsequent installment.

Excellent news: That any person could possibly be you. Drawings will show you how to make extra exact elements, even when your instruments haven’t modified. However when you’ve designed one thing that’s past your skills to provide, a drawing will prevent money and time at your native machine store. Plus, it’s going to rework you from an annoying newbie into one other skilled they’re comfortable to cope with. Okay, they’ll nonetheless be disenchanted you don’t wish to have 1000 of your elements made, however the odds of being informed no lower whenever you stroll within the door with a drawing.

Even higher, you possibly can add a 3D CAD mannequin of your half to a mail-order on-line machine store. Which means you possibly can design a component and have it shipped to your door with out leaving your desk. One warning, although: Even on-line retailers can cost a fairly penny for machining short-run elements.

What when you don’t wish to pay any person else to make your elements and would fairly do it your self? It’s time to begin shopping for some gear–which we’ll cowl within the subsequent installment.

Trending Merchandise