Should you’ve ever used a drill to show a spherical gap into an oval–it’s okay to confess it–then you definately perceive the essential concept behind a mill. As we defined within the final installment of “Making Stuff,” a lathe spins the work whereas holding the instrument regular, whereas a mill spins the instrument whereas holding the work regular.

Particularly when it’s paired with a lathe, only a few elements of a race automobile are off limits. Want to chop a keyway in that shaft? Construct brake caliper brackets? Adapt a brand new transmission to that engine? Make your personal gears? Or just make a slot in a bit of steel? A mill can do all of it and extra.

Forms of Mills

There are numerous forms of mills, and we have been trying to find one which slot in our storage and was versatile sufficient for all kinds of automotive initiatives. However past that, we didn’t actually know what we wished.

Our first intuition was to purchase a generic, imported 3-in-1 machine, as we had some expertise with one. These value just a few thousand {dollars} and mix a small mill and a lathe in a single machine that’s comparatively transportable. What’s the third perform that provides them their title? They’re technically drill presses, too. Advertising and marketing!

Right here’s why we determined in opposition to the 3-in-1. First, we weren’t glad with the scale of the work envelope or the rigidity of the machine. Second, we talked at size with pal of GRM and grasp machinist Steve Eckerich, and he was frank: “Don’t purchase a benchtop mill or a 3-in-1 at any value for any motive. You’ll be pissed off and restricted, and also you’ll find yourself going out to purchase a greater machine anyway. Don’t do it twice.”

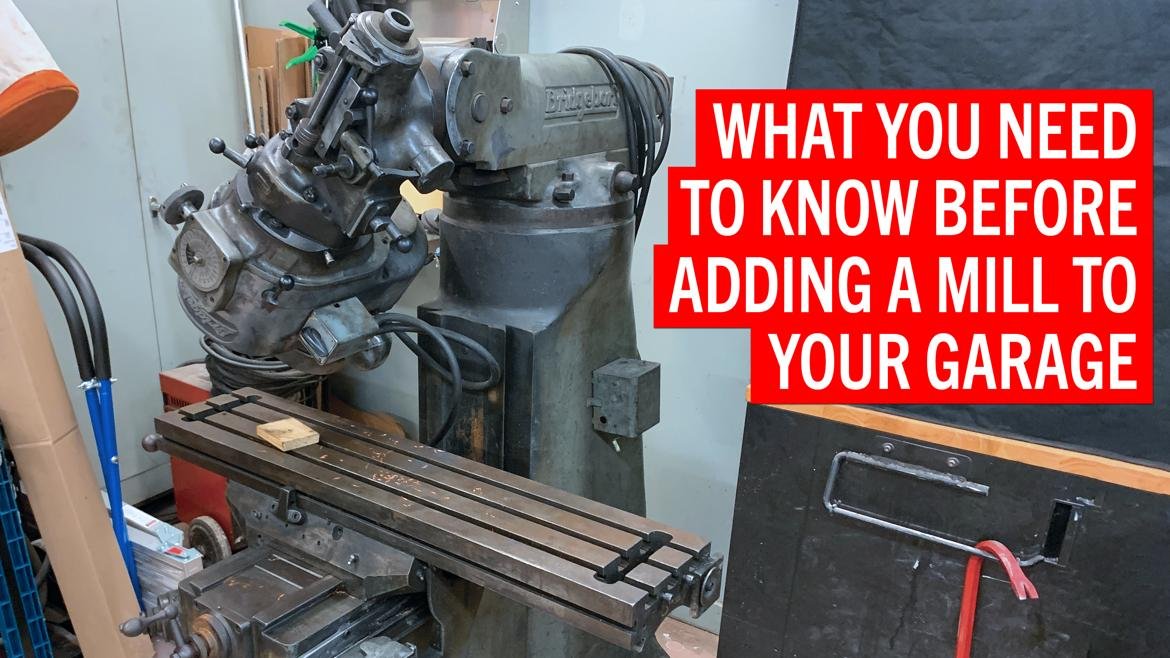

This recommendation was from a man who spends all day daily in a machine store and has constructed a zillion quick automobiles, so we figured it was value following. “You need a Bridgeport,” Steve stated. “Interval.”

What’s a Bridgeport?

Steve had some extent. Bridgeport is only a model title, not a kind of instrument, however identical to Kleenex is synonymous with tissues, Bridgeport is synonymous with vertical knee mills.

This dimension and magnificence of mill is extraordinarily adaptable to totally different jobs, comparatively small and compact, and inflexible and correct sufficient to do actual work. That’s why you’ll discover a Bridgeport, or a clone, in nearly each machine store–even trendy retailers full of high-priced CNC machines. As Steve defined, all people wants a Bridgeport within the nook, because it’s excellent for making a small half or two to your different machines, constructing fixtures, doing small one-off jobs and extra.

Since Bridgeports are so standard, a bunch of different corporations copied the design and constructed their very own vertical knee mills. There are many totally different model names and plenty of totally different ranges of high quality. These copies vary from “just about simply nearly as good as the actual factor” to “costly paperweight.” And to make issues extra sophisticated, the standard of the copies has modified drastically over time because the market shifted. Enjoyable!

Do you save any cash by shopping for a Bridgeport clone? Should you’re shopping for new, completely. However for those who’re shopping for used, particularly on the backside finish of the market like we have been, then not likely.

If something, costs appear to be primarily based totally on situation and included tooling somewhat than on the title on the facet. For machines in equal situation, we guesstimate a Bridgeport is value $500 to $1000 extra.

With all this in thoughts, we determined to spend a bit extra and purchase an actual Bridgeport. We figured the assured high quality, assured availability of substitute elements, and assured documentation and group help would make it well worth the value premium. If we knew extra about these machines and will immediately inform if we have been taking a look at clone or a nasty clone, we most likely would have been extra considering an off model.

Transporting Our Mill

Wait, shouldn’t we speak about shopping for a mill earlier than we speak about transporting one? Nope: It is a top-heavy, 2000-pound object that has no wheels, which suggests it’s very laborious to move.

Pickup truck beds don’t have robust sufficient tie-downs to safe a mill, our aluminum automobile trailer can’t help that a lot mass in a 2-foot sq., and each answer may require two forklifts, one at every finish of the transaction.

For that reason, the asking value is just one piece of the actual value of the mill. Purchase at public sale, and you will discover your self paying $100 to the forklift driver simply to load it in your trailer. Purchase privately, and you might want to rent a tow truck or a forklift to put it in your trailer. Or you possibly can pay a rollback to ship it door to door, however that’s very costly for something greater than an across-town transfer.

Many sellers provide to load for you, however you continue to want a plan to unload it once you get house. There’s additionally freight transport, which was too costly for us to think about.

Machine instruments are notoriously difficult to move, however vertical knee mills specifically are fragile, top-heavy and laborious to maneuver with no forklift. We wanted to do our homework earlier than we might make a purchase order.

The best choice, in our opinion, is renting a hydraulic drop-deck trailer, which lowers the deck to the bottom for straightforward loading and unloading. With one in all these and a come-along, you possibly can roll the mill on and off utilizing half-inch iron pipe with out an excessive amount of hazard. We spent $100 to lease one for the weekend.

What does all this imply when procuring? Easy: Distance issues.

We received’t hesitate to drive three states away to purchase a automobile, however transporting a mill drains cash out of your pockets each step of the way in which. We stay in Florida, so we merely couldn’t afford to retrieve one from a spot like Pennsylvania, the place there’s a lot of manufacturing and due to this fact a lot of used mills on the market. Meaning we had fewer choices and better costs than any individual who lives close to a extra industrial space.

Shopping for Our Bridgeport

We’d accomplished our homework, discovered transportation, and even bought an outdated Fox-body Mustang to unlock some area and money for our new mill. It was lastly time to buy groceries.

We opened the classifieds and searched–and searched and searched. We shopped casually for a yr or so, realizing that $1500 to $2000 Bridgeports have been few and much between. And after they did seem, they’d promote inside hours.

We misplaced one $1500 mill after we wanted 24 hours to lease the trailer. We suspect that through the ready interval, the vendor determined the value was too low, as he canceled the sale.

Lastly, after noticing costs have been growing, we realized it was now or by no means. We practically received a Summit vertical knee mill at a neighborhood public sale. It broke our clone rule, however it was solely 3 miles from our house, had a digital readout and gave the impression to be properly stored. We stopped bidding at $2100, an quantity that didn’t embrace any loading charges. Darn.

Then we heard by the grapevine {that a} pal of a pal–really, the unique proprietor of the Basic Motorsports Mini Cooper S undertaking automobile–had an additional Bridgeport he’d be prepared to promote. After just a few months of cajoling and negotiating, we purchased it for $2000. It was on the prime of our funds and lacking just a few handles, however the variable velocity head (principally a snowmobile CVT) made it well worth the value.

We rented a drop-deck trailer for $100, and it was value each penny.

We rented the flamboyant trailer, stuffed an envelope of Fox-body money in our pocket, and made the 7-hour spherical journey to tug it house. Shoutout to longtime pal of GRM Rennie Bryant for serving to us load the machine.

As soon as house, we moved the mill into the nook of our storage with no forklift. How? Meet the Burke Bar. It’s an enormous pry bar that’s excellent for wedging underneath the machine and selecting it as much as place iron pipe beneath. We grabbed ours from Lowe’s for $65.

The mill, although, wanted some restoration earlier than we might use it–however no less than it got here with a fascinating digital readout. Subsequent, we’ll restore that used mill.

After rolling the machine on the pipe to the again of our storage, we would have liked to spin it 180 levels. Right here’s one other trick: By coating the ground with dish cleaning soap, we have been in a position to take away the pipe and spin the mill by hand. Our Bridgeport had reached its new house.

Subsequent, we’ll restore our new discover after which put it to make use of.

Trending Merchandise